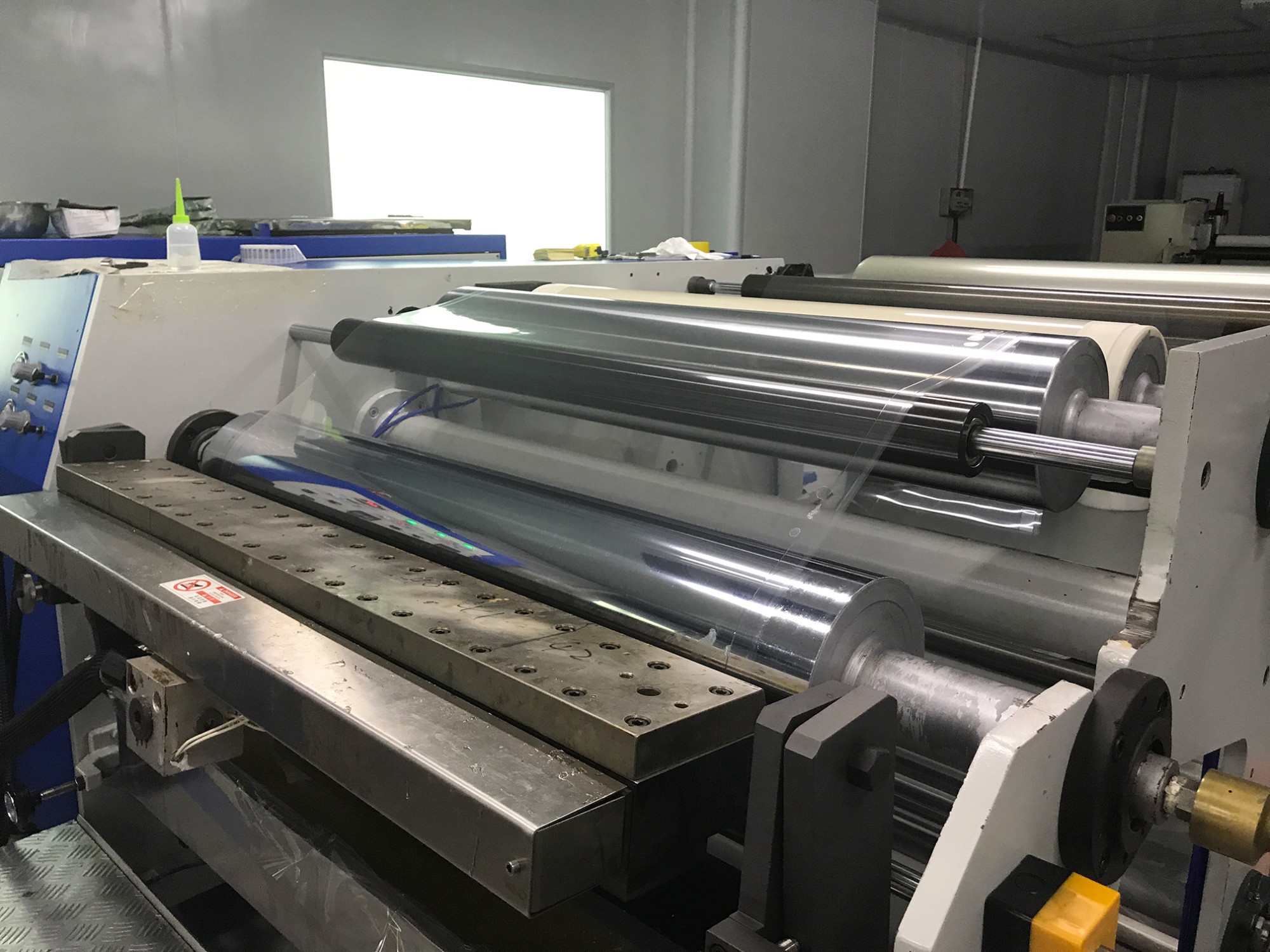

Hot melt adhesive casting machine

- Product Item : JSD-L320A-1

- Category: Lab Cast Film Machine

- Hot melt adhesive casting machine

- 3-layer co extrusion casting film machine

- laboratory PE casting and stretching film machine

- laboratory PE casting and stretching film machine

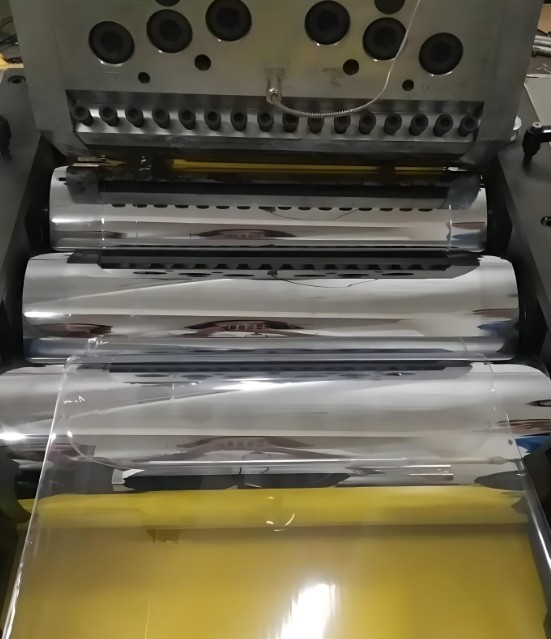

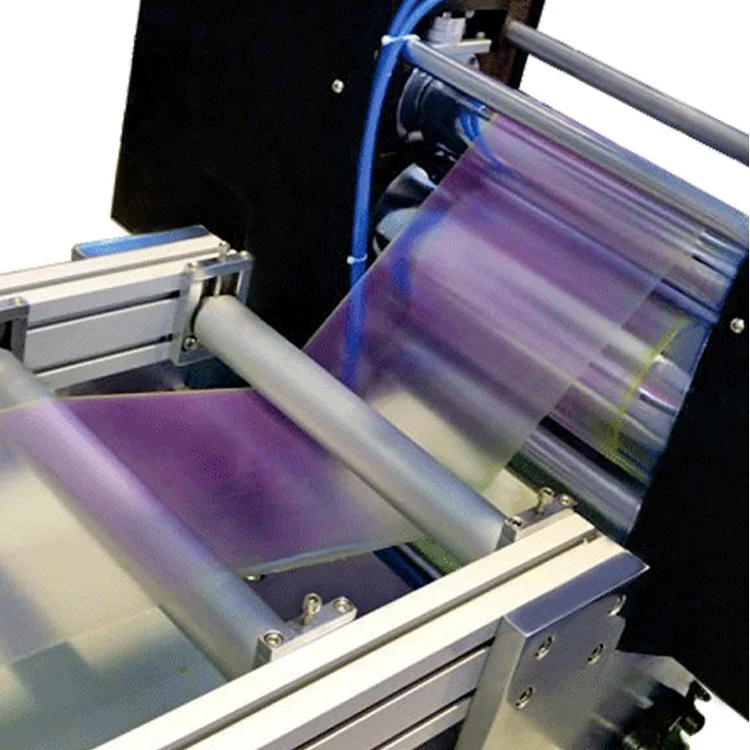

Rapid melting of hot melt adhesive and PET rolling forming

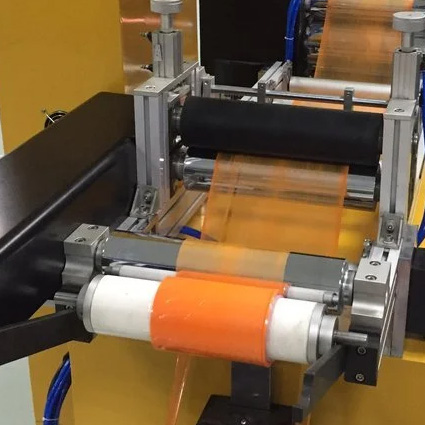

Coating and composite: The casting machine uses a coating device to coat other materials (such as paper, aluminum foil, etc.) onto the surface of the film, achieving coating or composite of the film. The coating device can be adjusted as needed to control the thickness and uniformity of the coating.

Optional glue box 50L-100L

Key attributes

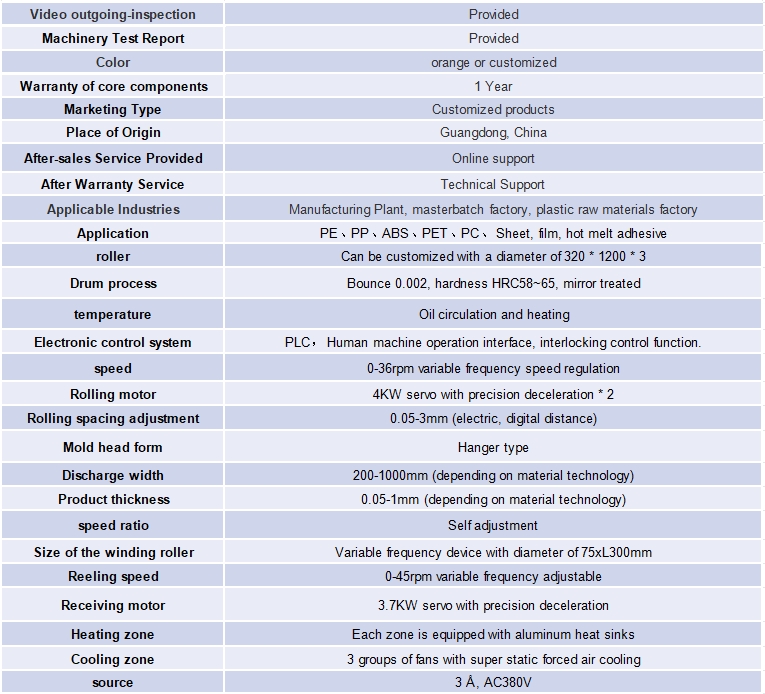

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Color | orange or customized |

| Warranty of core components | 1 Year |

| Marketing Type | Customized products |

| Place of Origin | Guangdong, China |

| After-sales Service Provided | Online support |

| After Warranty Service | Technical Support |

| Applicable Industries | Manufacturing Plant, masterbatch factory, plastic raw materials factory |

| Application | PE、PP、ABS、PET、PC、 Sheet, film, hot melt adhesive |

| roller | Can be customized with a diameter of 320 * 1200 * 3 |

| Drum process | Bounce 0.002, hardness HRC58~65, mirror treated |

| temperature | Oil circulation and heating |

| Electronic control system | PLC, Human machine operation interface, interlocking control function. |

| speed | 0-36rpm variable frequency speed regulation |

| Rolling motor | 4KW servo with precision deceleration * 2 |

| Rolling spacing adjustment | 0.05-3mm (electric, digital distance) |

| Mold head form | Hanger type |

| Discharge width | 200-1000mm (depending on material technology) |

| Product thickness | 0.05-1mm (depending on material technology) |

| speed ratio | Self adjustment |

| Size of the winding roller | Variable frequency device with diameter of 75xL300mm |

| Reeling speed | 0-45rpm variable frequency adjustable |

| Receiving motor | 3.7KW servo with precision deceleration |

| Heating zone | Each zone is equipped with aluminum heat sinks |

| Cooling zone | 3 groups of fans with super static forced air cooling |

| source | 3 Å, AC380V |

Packaging and delivery

Packaging Details

Wooden case

Supply Ability

Supply Ability

22 Set/Sets per Month

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China