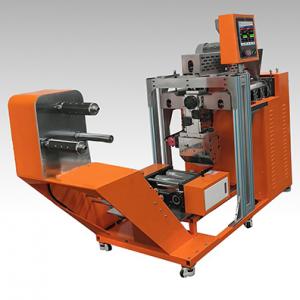

Lab Cast Film Machine

Used for LDPE/CPE/TPE/TPU/PET PVC material screws

Extrusion and cooling: The casting machine heats and melts plastic particles or particle mixtures through an extrusion system, and extrudes the molten plastic into thin films through screws. Subsequently, the extruded film is rapidly cooled through a cooling system to solidify it.

Coating and composite: After cooling, the casting machine uses a coating device to coat other materials (such as paper, aluminum foil, etc.) onto the surface of the film, achieving coating or composite of the film. The coating device can be adjusted as needed to control the thickness and uniformity of the coating.

Control system: The casting machine is usually equipped with a control system to monitor and adjust parameters such as extrusion temperature, coating speed, cooling speed, etc. This helps to ensure the quality and consistency of the coating or composite.

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China