High-Speed Automatic Plant Extruder Machine 3/5 Layer Cast Cling PE Stretch Film for LDPE/CPE/TPE/TPU/PET PVC Material Screw China machine

- Product Item : JSD-L20A-1

- Category: Lab Cast Film Machine

- Multi layer co extrusion casting film machine

- 3-layer co extrusion casting film machine

- laboratory PE casting and stretching film machine

- laboratory PE casting and stretching film machine

Used for LDPE/CPE/TPE/TPU/PET PVC material screws

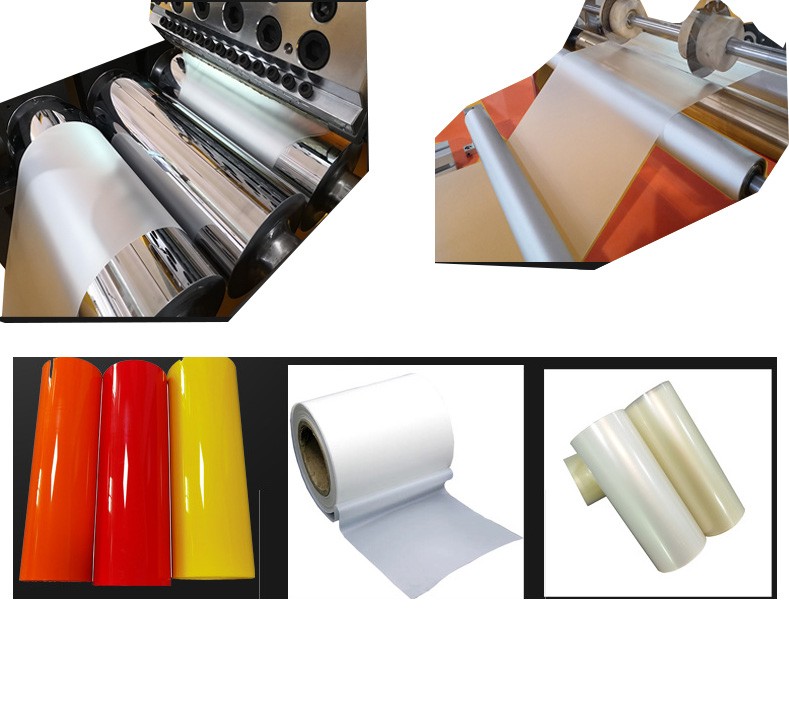

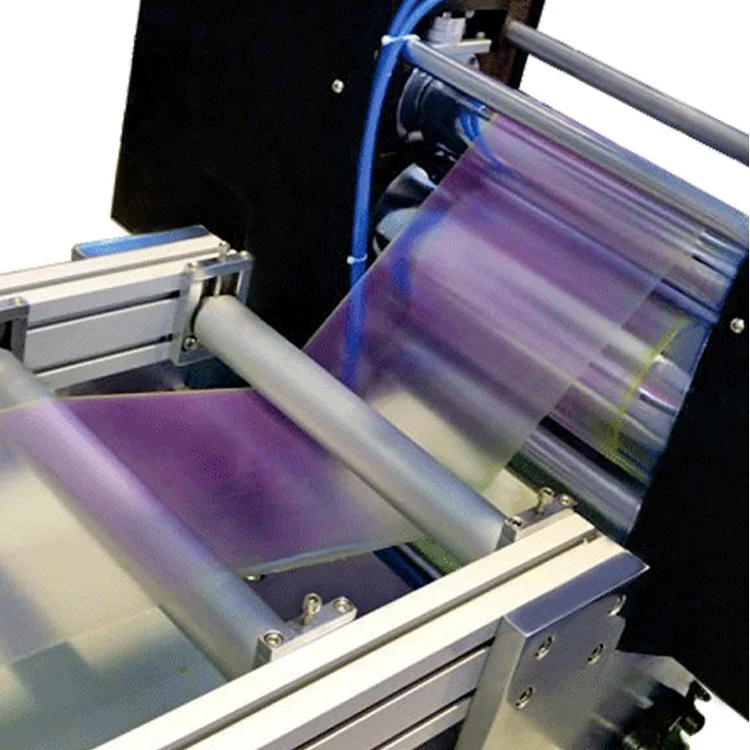

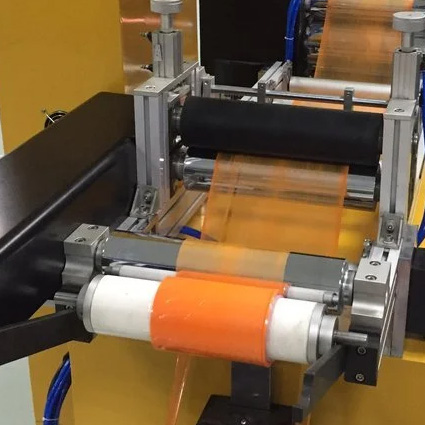

Extrusion and cooling: The casting machine heats and melts plastic particles or particle mixtures through an extrusion system, and extrudes the molten plastic into thin films through screws. Subsequently, the extruded film is rapidly cooled through a cooling system to solidify it.

Coating and composite: After cooling, the casting machine uses a coating device to coat other materials (such as paper, aluminum foil, etc.) onto the surface of the film, achieving coating or composite of the film. The coating device can be adjusted as needed to control the thickness and uniformity of the coating.

Control system: The casting machine is usually equipped with a control system to monitor and adjust parameters such as extrusion temperature, coating speed, cooling speed, etc. This helps to ensure the quality and consistency of the coating or composite.

Multi functional application: The casting machine is widely used in the packaging industry, such as food packaging, pharmaceutical packaging, industrial packaging, etc. It can manufacture various types of coated or composite films to meet the needs of different industries.

It should be noted that when using the casting machine, operating procedures and safety precautions should be followed to ensure the normal operation of the equipment and the safety of personnel. In addition, depending on specific plastic materials and coating/composite requirements, it may be necessary to choose the appropriate casting machine model and configuration.

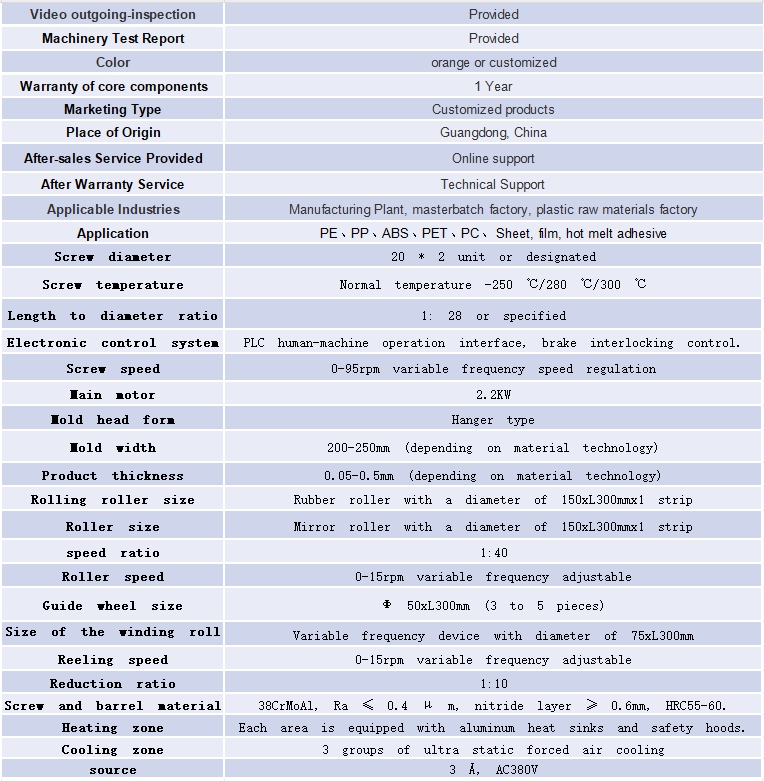

Key attributes

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Color | orange or customized |

| Warranty of core components | 1 Year |

| Marketing Type | Customized products |

| Place of Origin | Guangdong, China |

| After-sales Service Provided | Online support |

| After Warranty Service | Technical Support |

| Applicable Industries | Manufacturing Plant, masterbatch factory, plastic raw materials factory |

| Application | PE、PP、ABS、PET、PC、 Sheet, film, hot melt adhesive |

| Screw diameter | 20 * 2 unit or designated |

| Screw temperature | Normal temperature -250 ℃/280 ℃/300 ℃ |

| Length to diameter ratio | 1: 28 or specified |

| Electronic control system | PLC human-machine operation interface, brake interlocking control. |

| Screw speed | 0-95rpm variable frequency speed regulation |

| Main motor | 2.2KW |

| Mold head form | Hanger type |

| Mold width | 200-250mm (depending on material technology) |

| Product thickness | 0.05-0.5mm (depending on material technology) |

| Rolling roller size | Rubber roller with a diameter of 150xL300mmx1 strip |

| Roller size | Mirror roller with a diameter of 150xL300mmx1 strip |

| speed ratio | 1:40 |

| Roller speed | 0-15rpm variable frequency adjustable |

| Guide wheel size | Φ 50xL300mm (3 to 5 pieces) |

| Size of the winding roller | Variable frequency device with diameter of 75xL300mm |

| Reeling speed | 0-15rpm variable frequency adjustable |

| Reduction ratio | 1:10 |

| Screw and barrel material | 38CrMoAl, Ra ≤ 0.4 μ m, nitride layer ≥ 0.6mm, HRC55-60. |

| Heating zone | Each area is equipped with aluminum heat sinks and safety hoods. |

| Cooling zone | 3 groups of ultra static forced air cooling |

| source | 3 Å, AC380V |

Packaging and delivery

Supply Ability

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China