Small face picosecond laser cutting machine

- Product Item : JSD-G4030A-1

- Category: Laser equipment

- FPC Laser Splitting Machine

- Small face picosecond laser cutting machine

- Saw blade slitting machine

- Non metallurgical tool splitting machine

Small face picosecond laser cutting machine

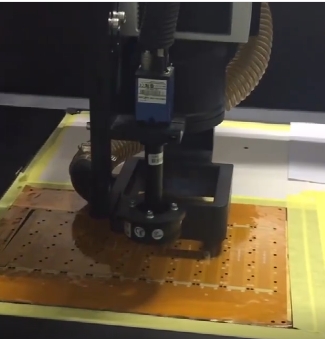

This is a small surface picosecond laser cutting machine developed for scientific research institutions, with higher accuracy and wider applicability. It is designed for precise cutting and drilling of sensor chips, PET, PI, PVC film materials, ceramic sheets, metal layer silver slurry etching, metal foil and other materials.

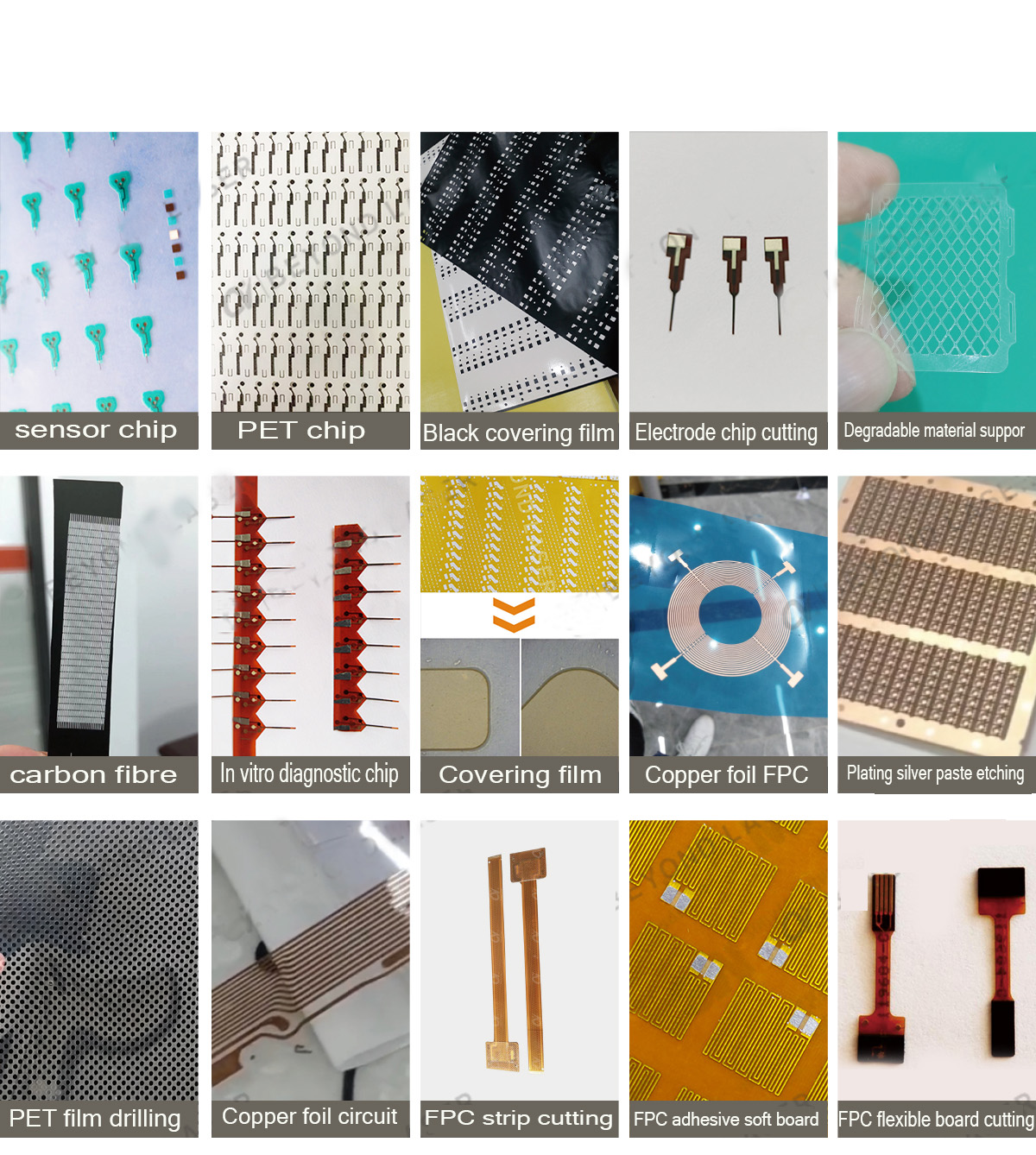

Materials that can be processed: electrode chips, FPC shapes, FPC auxiliary materials, PET, PI films, ceramic sheets, various thin films, etc

High processing accuracy: small format platform, automatic positioning and focusing, higher accuracy

Structural optimization: Fine cutting of various materials, etching of lines, and drilling of micro holes are very suitable for shaping

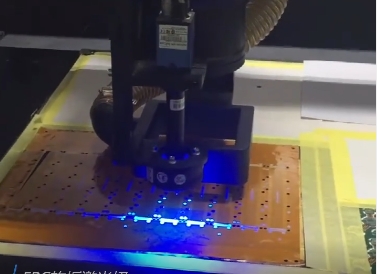

Stable and environmentally friendly: smoking up and down, electrostatic technology, and vacuum adsorption platform are more stable and environmentally friendly

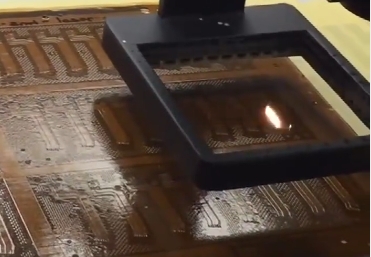

Edge effect: minimal heat effect, smooth and tidy, carbonized 5-20 μ m

Output pulse width ≤ 15ps,

Processing accuracy of 20 ± 5 μ m,

CCD alignment accuracy ± 5 μ m

Applicable scope mainly applies to industries such as PCB, CVL, FPC, RF, etc; Cutting various types of films and auxiliary materials such as FPC soft board, covering film, PET film, PI film, PP film, adhesive film, copper foil, explosion-proof film, electromagnetic film, FR4, 3M adhesive, PI reinforcement, PE film, etc. It can also be used to cut various substrates, such as ceramics, silicon wafers, aluminum foil, PTFE, etc.

##Marble base

Gantry structure, marble columns

The high rigidity of the crossbeam body

Stability and seismic resistance

##Z-axis design

High precision Z-axis design,

Adjust the laser focal length to ensure cutting

The high precision of the product

##Humanized operation

Fully realize equipment automation throughout the process

One click operation, clear button operation,

Within reach

##High strength body

Ductile iron welded body,

Completely eliminate stress and reduce body deformation,

Ensure accuracy remains unchanged for a long time

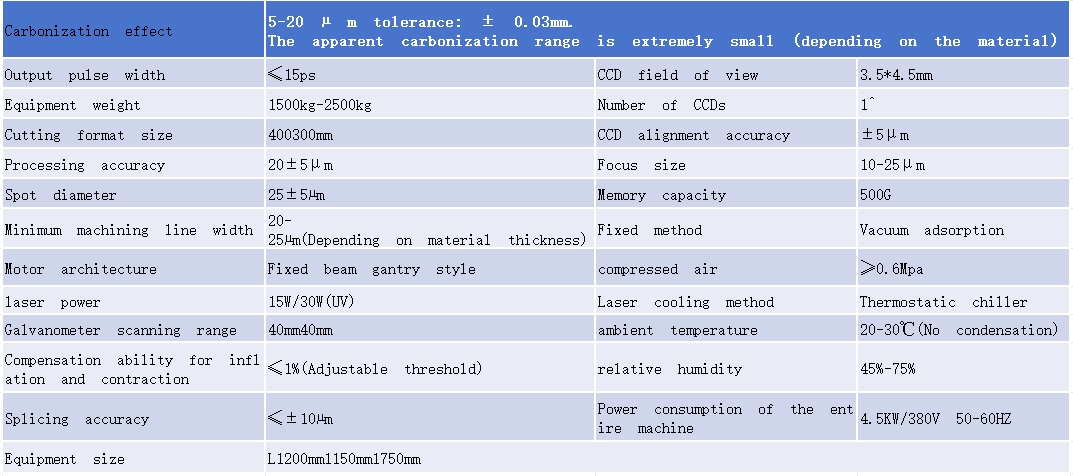

| Carbonization effect |

5-20 µ m tolerance: ± 0.03mm.

The apparent carbonization range is extremely small (depending on the material)

|

||

| Output pulse width | ≤15ps | CCD field of view | 3.5*4.5mm |

| Equipment weight | 1500kg-2500kg | Number of CCDs | 1^ |

| Cutting format size | 400300mm | CCD alignment accuracy | ±5μm |

| Processing accuracy | 20±5μm | Focus size | 10-25μm |

| Spot diameter | 25±5µm | Memory capacity | 500G |

| Minimum machining line width | 20-25µm(Depending on material thickness) | Fixed method | Vacuum adsorption |

| Motor architecture | Fixed beam gantry style | compressed air | ≥0.6Mpa |

| laser power | 15W/30W(UV) | Laser cooling method | Thermostatic chiller |

| Galvanometer scanning range | 40mm40mm | ambient temperature | 20-30℃(No condensation) |

| Compensation ability for inflation and contraction | ≤1%(Adjustable threshold) | relative humidity | 45%-75% |

| Splicing accuracy | ≤±10µm | Power consumption of the entire machine | 4.5KW/380V 50-60HZ |

| Equipment size | L1200mm1150mm1750mm | ||

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China