Automatic pulse welding machine

- Product Item : JSD-B001A-1

- Category: PCB slitting machine

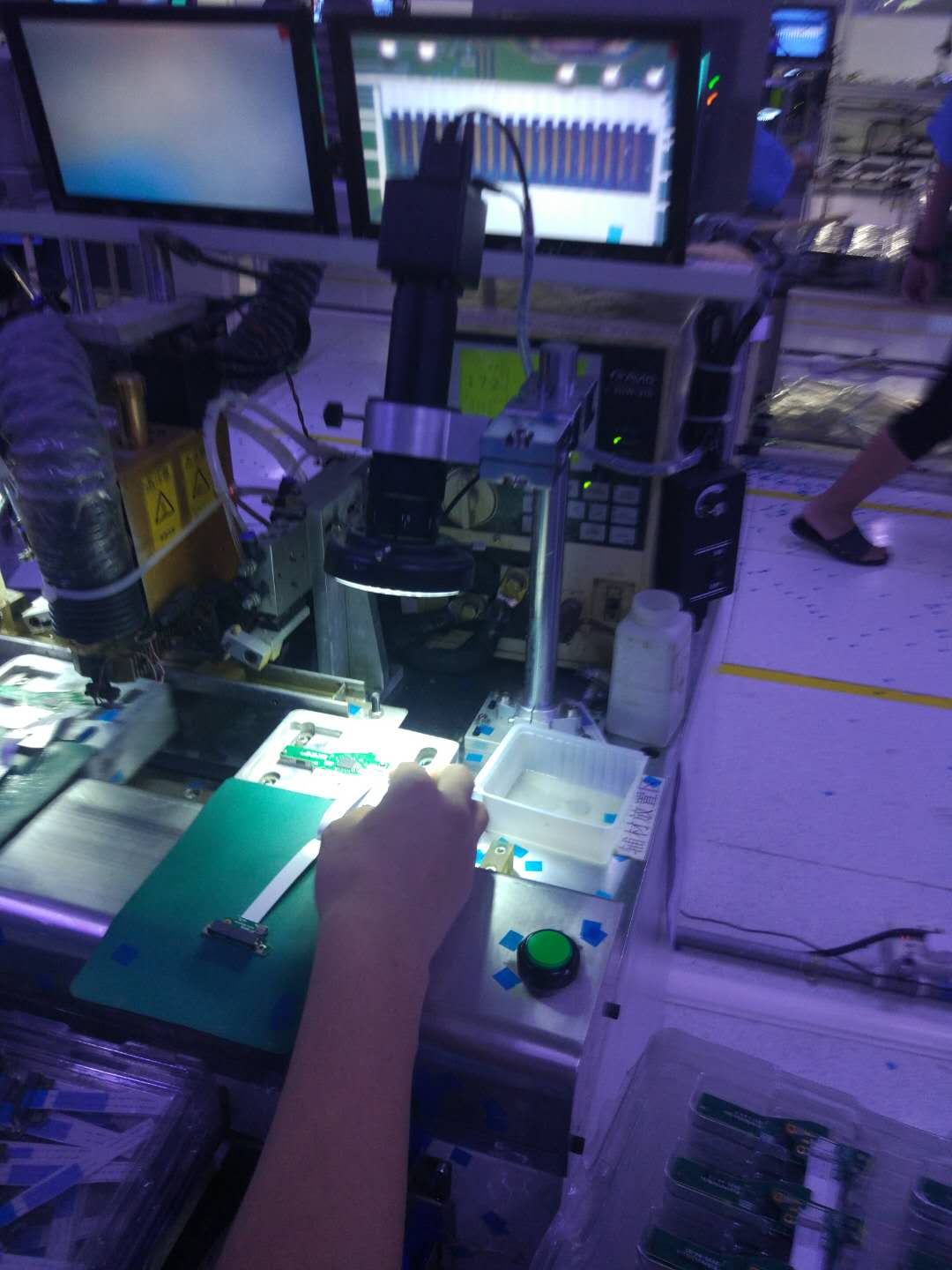

- Automatic pulse welding machine

- PCB Splitting and Swinging Integrated Machine

- Saw blade slitting machine

- Non metallurgical tool splitting machine

Suitable for hot pressing welding between high-density FPC, FFC and PCB, connectors, ink cartridge chip welding, plastic hot pressing riveting and other processes. Widely used in industries such as automobiles, power supplies, computers, home appliances, mobile phones, connectors, printers, LEDs, etc

Features of automatic pulse welding machine:

1. Temperature CNC, clear and precise;

2. Equipped with a digital pressure switch that can preset the pressure range;

3. Pressure start timer for more accurate hot pressing time;

4. Unique material welding head ensures even compression of the product;

5. Equipped with vacuum function, it is easier to adjust alignment;

Applicable to:

Solder connections between FPC and PCB, connectors between ACF and PCB, connectors between TAB and PCB, connectors between TFT and PCB, and connectors between connectors

Solder connection between FFC (flexible flat cable) and PCB, connectors

The soldering strontium connection between the Bama paper and PCB, as well as the soldering connection between the coaxial line and the PCB and connector

Solder strontium connection of enameled wires such as hard drives, resistors, capacitors, coils, transformers, IC cards, etc

Tin connections between battery electrodes, PCBs, and connectors

Solder connection of winding terminals for small motors

Resin hot pressing bonding of relays, printers, glasses, etc

Welding ribbon cable:

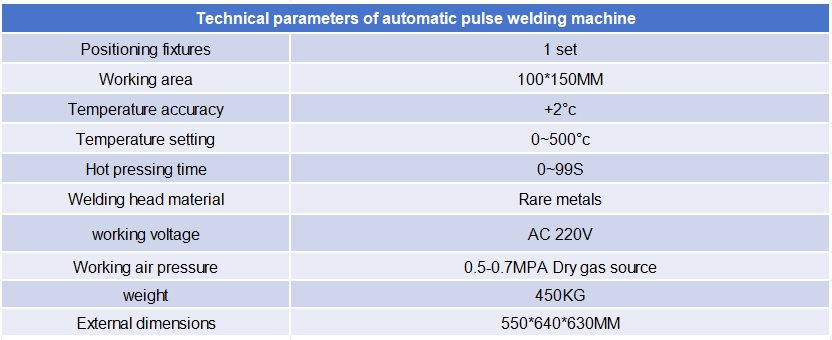

| Technical parameters of automatic pulse welding machine | |

| Positioning fixtures | 1 set |

| Working area | 100*150MM |

| Temperature accuracy | +2°c |

| Temperature setting | 0~500°c |

| Hot pressing time | 0~99S |

| Welding head material | Rare metals |

| working voltage | AC 220V |

| Working air pressure | 0.5-0.7MPA Dry gas source |

| weight | 450KG |

| External dimensions | 550*640*630MM |

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China

-tablet-press-P310A3e.97.1.jpg)