Explosion constant temperature and humidity test chamber

- Product Item : JSD-T102A-1

- Category: Detection equipment

- Ozone resistance testing machine

- Explosion constant temperature and humidity test chamber

- temperature humidity test chamber

- temperature and humidity chamber

Application of small constant temperature and humidity test chamber:

The constant temperature and humidity testing chamber, also known as the constant temperature and humidity testing chamber, is mainly used as an equipment to test the performance of industrial samples in high and low temperature humid and hot environments, and to test the physical changes of various samples in a comprehensive environment of constant high temperature (i.e. high temperature), constant low temperature (i.e. cold resistance), and constant humidity (i.e. humidity). Mainly used in industrial industries such as laboratories (such as schools, research institutes, and enterprise quality departments).

Characteristics of a 100L small constant temperature and humidity test box:

1.1.1. Inner box material: SUS304 # (1.2mm thick) 8K mirror stainless steel plate is used, which has advantages such as acid resistance, corrosion resistance, and easy cleaning.

1.1.2. Outer box material: cold-rolled steel plate with baking paint treatment, 1.2mm thick.

1.1.3. Insulation and noise: The insulation layer is made of polyurethane foam, which is lightweight, durable, and corrosion-resistant. The box door is sealed with magnetic tape, with a beautiful appearance and high temperature control accuracy; The connecting parts of the inner and outer boxes are made of non-metallic materials that are resistant to high and low temperatures, effectively reducing temperature conduction; The humidification method adopts isolated humidification; Equipped with a sealed refrigeration unit, it runs smoothly and has low noise. The stainless steel finned heating tube heats the air, preventing rust and corrosion.

1.1.4. Sample holder: Made of SUS304 # stainless steel punched and bent into a mesh, convenient and beautiful, with adjustable spacing; Two standard configurations, evenly distributed samples with a load capacity of ≤ 25kg.

1.1.5. Test hole: Open a test hole with a diameter of 50mm, and attach corresponding insulation accessories and specialized sealing soft plugs.

1.1.6. Observation window: Double layer vacuum reinforced glass is used, and the inner side is bonded with a conductive film for heating and defrosting, allowing for clear observation of the test process inside the box.

1.1.7. Door handle: Adopting non reactive and explosion-proof door handles, easy to operate, safe and reliable.

1.1.8. Mobile and positioning device: High quality universal casters with brakes are installed at the bottom of the machine, which can easily and quickly move the machine to the designated position and fix the machine.

Execution and compliance with standards:

● GB/T10589-1989 Technical Conditions for Low Temperature Test Boxes ● GB/T10586-1989 Technical Conditions for Damp Heat Test Boxes,

● GB/T10592-1989 Technical conditions for high and low temperature test chambers ● GB2423.1-89 Low temperature test Aa, Ab

● GB2423.1-93 (IEC68-2-3) Constant Damp Heat Test Ca ● MIL-STD810D Method 502.2

● GB/T2423.4-93 (MIL-STD810) Method 507.2 Procedure 3 ● GJB 150.9-8 Temperature Test

GB2423.34-86, MIL-STD883C Method 1004.2 Temperature and Humidity Combined Cycle Test

A small constant temperature and humidity test chamber, a small constant temperature and humidity machine, and a miniature constant temperature and humidity test chamber are equipment used to test the performance of materials in various environments and to test the heat resistance, cold resistance, dry resistance, and moisture resistance of various materials. Suitable for testing the quality of electronic, electrical, mobile, communication, instrumentation, vehicles, plastic products, metals, food, chemistry, building materials, aerospace and other products; Based on the testing requirements of different products for customers, customized design can be carried out according to their actual needs, and testing solutions can be provided. At a low temperature of -40 ℃, the temperature and humidity alternating curve can be observed.

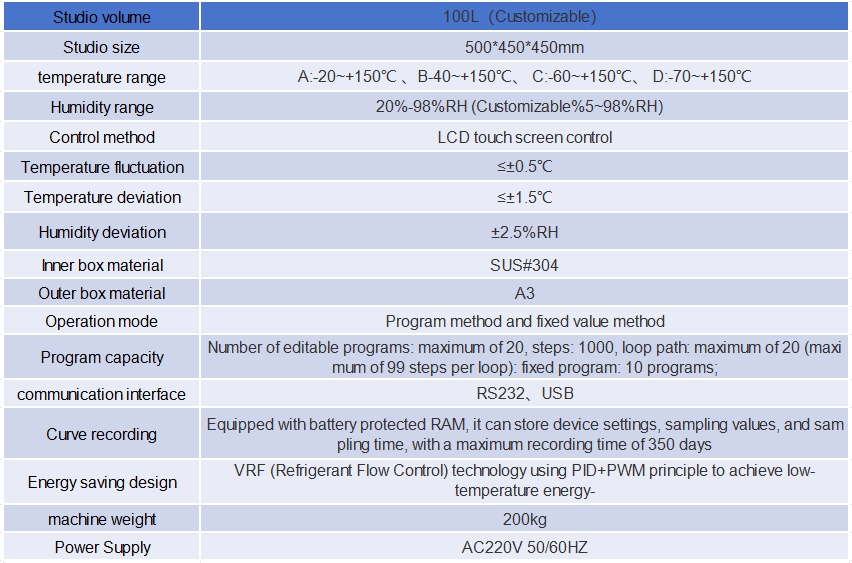

| Studio volume | 100L(Customizable) |

| Studio size | 500*450*450mm |

| temperature range | A:-20~+150℃ 、B-40~+150℃、 C:-60~+150℃、 D:-70~+150℃ |

| Humidity range | 20%-98%RH (Customizable%5~98%RH) |

| Control method | LCD touch screen control |

| Temperature fluctuation | ≤±0.5℃ |

| Temperature deviation | ≤±1.5℃ |

| Humidity deviation | ±2.5%RH |

| Inner box material | SUS#304 |

| Outer box material | A3 |

| Operation mode | Program method and fixed value method |

| Program capacity | Number of editable programs: maximum of 20, steps: 1000, loop path: maximum of 20 (maximum of 99 steps per loop): fixed program: 10 programs; |

| communication interface | RS232、USB |

| Curve recording | Equipped with battery protected RAM, it can store device settings, sampling values, and sampling time, with a maximum recording time of 350 days |

| Energy saving design | VRF (Refrigerant Flow Control) technology using PID+PWM principle to achieve low-temperature energy-saving operation equipped with cold control PID automatic adjustment technology |

| machine weight | 200kg |

| Power Supply | AC220V 50/60HZ |

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China