Extrusion filtration testing machine

- Product Item : JSD-J020A-1

- Category: Extruder

- Laboratory twin-screw extrusion granulation line

- Extrusion filtration testing machine

- PBAT film blowing machine

- high and low pressure polyethylene film blowing machine

Standard: The testing method complies with the European standard EN13900-5:2005 testing standard.

1、 Single screw extruder

Screw material: 38CrMoAl chromium molybdenum alloy, with surface treated by quenching, nitriding, chrome plating, polishing, and ultra precision grinding. The roughness Ra is ≤ 0.4 μ m, the depth of the nitriding layer is ≥ 0.6mm, and the hardness is HRC55-60.

Material of the barrel: 38CrMoAl chromium molybdenum alloy, with surface treated by quenching, nitriding, chrome plating, polishing, and ultra precision grinding. The roughness Ra is ≤ 0.4 μ m, the depth of the nitriding layer is ≥ 0.6mm, and the hardness is HRC55-60.

Heating zone: Zone 3 heater for material barrel, Zone 2 heater for machine head, with copper heat sinks in each zone and stainless steel safety fan cover on the outside.

Cooling area: 3 sets of multi wing fans with ultra static forced air cooling

Melt temperature: Dynisco high-precision temperature sensor monitors changes in melt temperature

Quick change device: C-type snap ring connection, easy to quickly connect with downstream equipment.

Electric control system: PLC programmable color touch screen, human-machine interface operation system, dynamic display and monitoring of extrusion process, including temperature control, drive, rotation rate, pressure and other interlocking control functions.

The filter shall refer to the EN13900-5:2005 standard. Aluminum frame wrapping, according to the European standard for screen pack 1/pack 2/pack 3 model size.

Program controller

PLC programmable color touch screen controller, human-machine interface operating system including pressure, temperature, and flow control modules, interlocking and closed-loop control for timely collection and capture

Capture the changes in melt temperature and pressure curves at every moment with a USB port, which can be connected to a printer to print test results, automatically generate test reports, and calculate filter pressure automatically

Force Value (FPV).

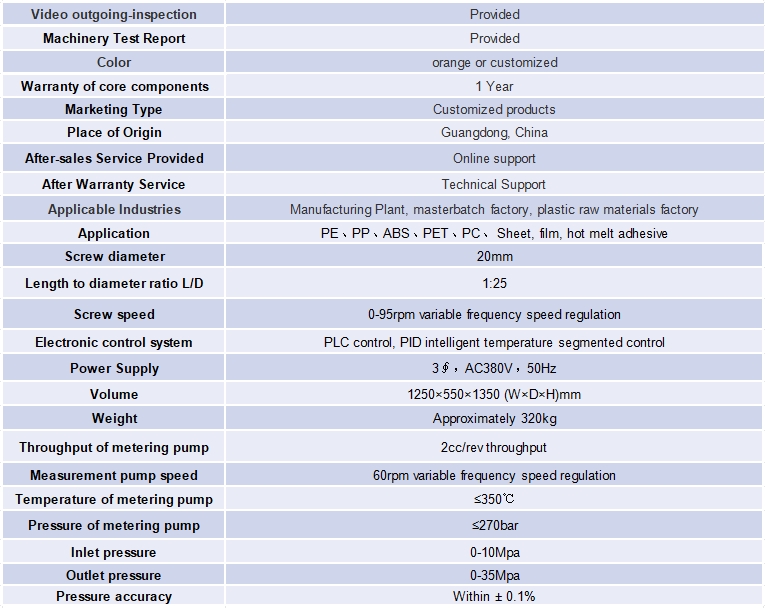

Key attributes

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Color | orange or customized |

| Warranty of core components | 1 Year |

| Marketing Type | Customized products |

| Place of Origin | Guangdong, China |

| After-sales Service Provided | Online support |

| After Warranty Service | Technical Support |

| Applicable Industries | Manufacturing Plant, masterbatch factory, plastic raw materials factory |

| Application | PE、PP、ABS、PET、PC、 Sheet, film, hot melt adhesive |

| Screw diameter | 20mm |

| Length to diameter ratio L/D | 1:25 |

| Screw speed | 0-95rpm variable frequency speed regulation |

| Electronic control system | PLC control, PID intelligent temperature segmented control |

| Power Supply | 3∮,AC380V,50Hz |

| Volume | 1250×550×1350 (W×D×H)mm |

| Weight | Approximately 320kg |

| Throughput of metering pump | 2cc/rev throughput |

| Measurement pump speed | 60rpm variable frequency speed regulation |

| Temperature of metering pump | ≤350℃ |

| Pressure of metering pump | ≤270bar |

| Inlet pressure | 0-10Mpa |

| Outlet pressure | 0-35Mpa |

| Pressure accuracy | Within ± 0.1% |

Packaging and delivery

Supply Ability

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China

-tablet-press-P310A3e.97.1.jpg)