Laboratory twin-screw extrusion granulation line

- Product Item : JSD-J030A-1

- Category: Extruder

- Laboratory twin-screw extrusion granulation line

- PLA film blowing machine

- PBAT film blowing machine

- high and low pressure polyethylene film blowing machine

Small twin-screw extruders can be widely used in PE twin-screw extrusion, PP twin-screw extrusion, PET twin-screw extrusion, etc; It is an ideal experimental equipment for high-precision and high-performance processing in the fields of plastic blending modification, filling modification, additive dispersion, fiber reinforcement, blending reaction, polymerization reaction, exhaust devolatilization, etc.

Application field of small twin-screw extruder granulation experimental line

1. Mixing and extrusion granulation of general plastics, engineering plastics, elastomers and other materials;

2. Blending modification and reactive extrusion of composite materials; 3、 Efficient mixing of polymer alloys;

4. 5. Research and development of new products and formulas for polymer filling enhancement and modification;

6. Optimization of production process parameters; 7、 Small production line.

Performance characteristics of a small twin-screw extruder granulation experimental line

1. The extruder is driven by a branded variable frequency motor, which ensures stable plasticization and good consistency;

2. Building block barrel and screw structure, convenient and fast process adjustment;

3. Quick opening machine head and screen changer, quick material cleaning and screen replacement;

4. Select Dynisco brand melt pressure and temperature sensors with high testing data accuracy;

5. A computer-based measurement and control system with a user-friendly operating interface makes it easy to control and more powerful in functionality;

6. Emergency shutdown devices and various safety protections ensure the safety of operators;

7. With the corresponding auxiliary equipment, it can be combined into experimental lines such as granulation, rolling, and casting films.

8. Highly intelligent and easy to operate.

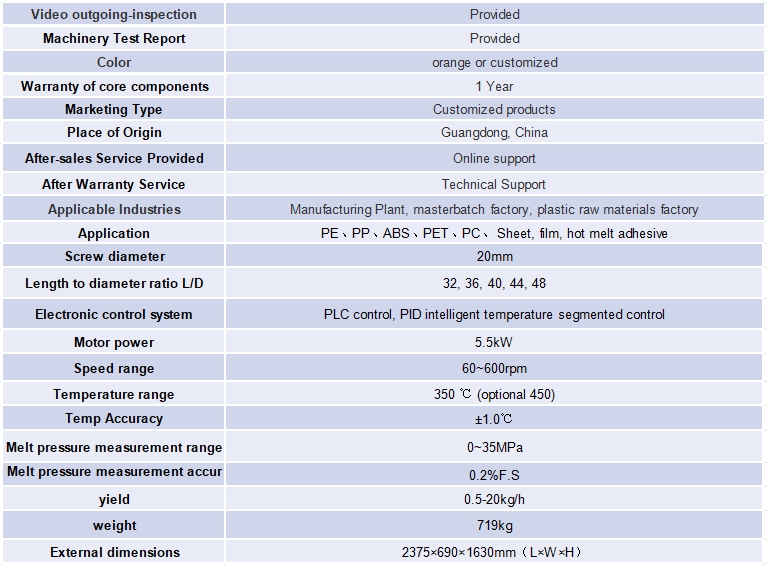

Key attributes

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Color | orange or customized |

| Warranty of core components | 1 Year |

| Marketing Type | Customized products |

| Place of Origin | Guangdong, China |

| After-sales Service Provided | Online support |

| After Warranty Service | Technical Support |

| Applicable Industries | Manufacturing Plant, masterbatch factory, plastic raw materials factory |

| Application | PE、PP、ABS、PET、PC、 Sheet, film, hot melt adhesive |

| Screw diameter | 20mm |

| Length to diameter ratio L/D | 32, 36, 40, 44, 48 |

| Electronic control system | PLC control, PID intelligent temperature segmented control |

| Motor power | 5.5kW |

| Speed range | 60~600rpm |

| Temperature range | 350 ℃ (optional 450) |

| Temp Accuracy | ±1.0℃ |

| Melt pressure measurement range | 0~35MPa |

| Melt pressure measurement accuracy | 0.2%F.S |

| yield | 0.5-20kg/h |

| weight | 719kg |

| External dimensions | 2375×690×1630mm(L×W×H) |

Packaging and delivery

Supply Ability

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China