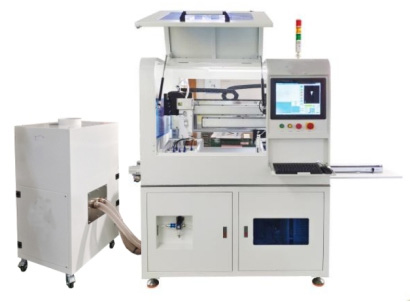

Saw blade slitting machine

- Product Item : JSD-B060A-1

- Category: PCB slitting machine

- Multifunctional slitting machine

- PCB Splitting and Swinging Integrated Machine

- Saw blade slitting machine

- Silicone open mill

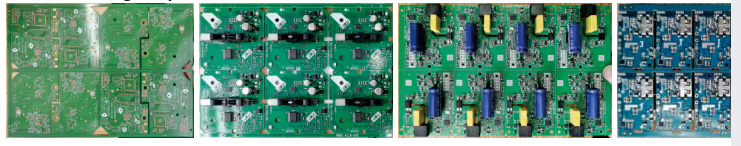

Suitable for composite PCB slitting connected to V-slots and stamp holes, especially for PCB slitting of parts crossing V-slots; Widely used in industries such as automobiles, power supplies, computers, home appliances, mobile phones, connectors, LEDs, etc

Features of Online Saw Blade Splitting Machine:

1. Realize unmanned production, suitable for cutting PCBA boards connected to V-CUT;

2. V-rough PCB sub boards suitable for fiberboard, aluminum substrate, and copper substrate;

3. Mark point automatic correction cutting solves the problem of incoming material deviation for different batches of products;

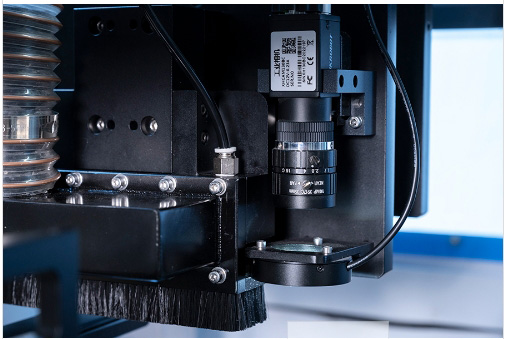

4. Capable of displaying cutting paths and images, with real-time correspondence between actual cutting paths and PCB images, and strong visualization;

5. Equipped with tool depth management function, suitable for deep cutting with components on the reverse side of the cutting point, ensuring good PCBA cutting without damaging the components;

6. Patent design for real-time cutting and dust removal technology;

7. Can completely solve the problem of cross V-slot cutting of components;

8. The stress on the dividing plate is extremely low, around 200MIC, and the cutting surface is smooth and bright;

Online saw blade slitting machine feeding method:

1. Anti static belt transmission method, seamless docking with SMT peripheral equipment;

2. The track width can be automatically adjusted, with an adjustment range of 50-350MM;

3. Adopting independent modular design, easy and fast installation;

Online saw blade slitting machine slitting structure:

1. Adopting servo motor combined with precision screw drive, effectively ensuring cutting speed and accuracy;

2. The saw blade cutter is driven by a high-speed brushless motor, effectively reducing cutting stress;

3. The saw blade is non stick and suitable for cutting aluminum substrates, copper substrates, FR4 and other sheets;

Online saw blade slitting machine grabbing mechanism:

1. The X-axis is driven by imported belts and closed-loop stepper motors, which have fast response speed, high accuracy, and low maintenance costs;

2. The material retrieval adopts a dual robotic arm independent operation method, which is high in efficiency, strong in flexibility, fast in changing lines, and equipped with abnormal product retrieval and placement alarms;

3. Equipped with multifunctional straight air suction nozzle, convenient and fast product line earning

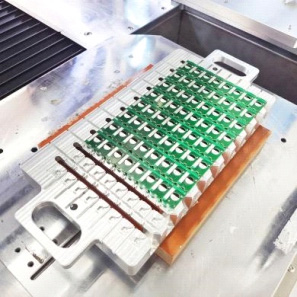

Using CCD visual automatic scanning and customized precision fixtures to ensure cutting accuracy.

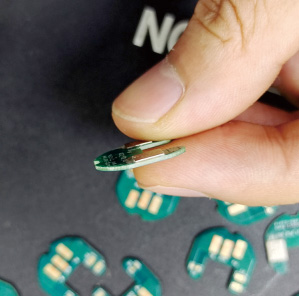

After the saw blade slitting machine cuts, the PCB end face is flat:

Online saw blade slitting machine dust collection system:

Sample of Online Saw Blade Splitting Machine Splitting:

1. Working mode: online

2. Number of workstations: single workstation

3. Splitting area: 300 * 300MM

4. Control method: PC control computer+servo

5. Splitting speed: 0-100MM/S

6. Component height: The height limit for the reverse part of the PCB is 10mm, and the height limit for the front part is 10mm

7. Repetitive accuracy: ± 0.02mm

8. Splitting accuracy: ± 0.05mm

9. Working voltage: AC 380 5KW

10. Working pressure: 0.5~0.7MPA

11. Spindle speed: 0~40000 RPM

12. Plate thickness ratio: 0-6mm

13. Vacuum suction method: upper suction

14. Weight: 800KG

15. External dimensions: length 1200 * width 1100 * height 1650mm

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China