China machine Laboratory Mixer Machine Plastic Rolling Mixer Open Two Roll Mill

- Product Item : JSD-K122A-2

- Category: Two Roll Mill

- China machine Laboratory Mixer Machine Plastic Rolling Mixer Open Two Roll Mill

- 9-inch Two Roll Mill

- PVC Two Roll Mill

- Silicone Two Roll Mill

Product Application

The lab two roll mill is used to mix the raw material and additional agents uniformly for testing, and apply the experiment

results and its ratio in the production line to satisfy the requirements of quality and color which specified by the customer.

Lab two roll mill is widely used in rubber, plastics industries. Such as polyolefin, PVC, film, coil, profile production and

polymer blending, pigments, masterbatch, stabilizers, stabilizers and so on. The main purpose is to test raw materials's physical properties change and contrast after mixing. Such as color dispersion, light transmission, substance table.

Addictives in the form of particles, powder, and liquid are allowed to be added as activators, fillers, or oils into the base.

With the rotation of the two rolls, the internal macromolecular chains of the raw materials are broken accordingly for

mastication, and the compositions inside the rubber compound are further dispensed to complete mixing, thus producing sheet-like materials for further molding desired products.

During the process, the operator needs to keep cutting, folding, and rolling the material on the front roll manually with a tool made of bamboo or wood to enhance the uniformity of the compositions.

1,Upgraded spacing display to digital display

2,Upgraded material blocking adjustment (optional automatic)

3,Upgrade of bracket structure

4,Upgrading the dovetail guide rail

Key attributes

Other attributes

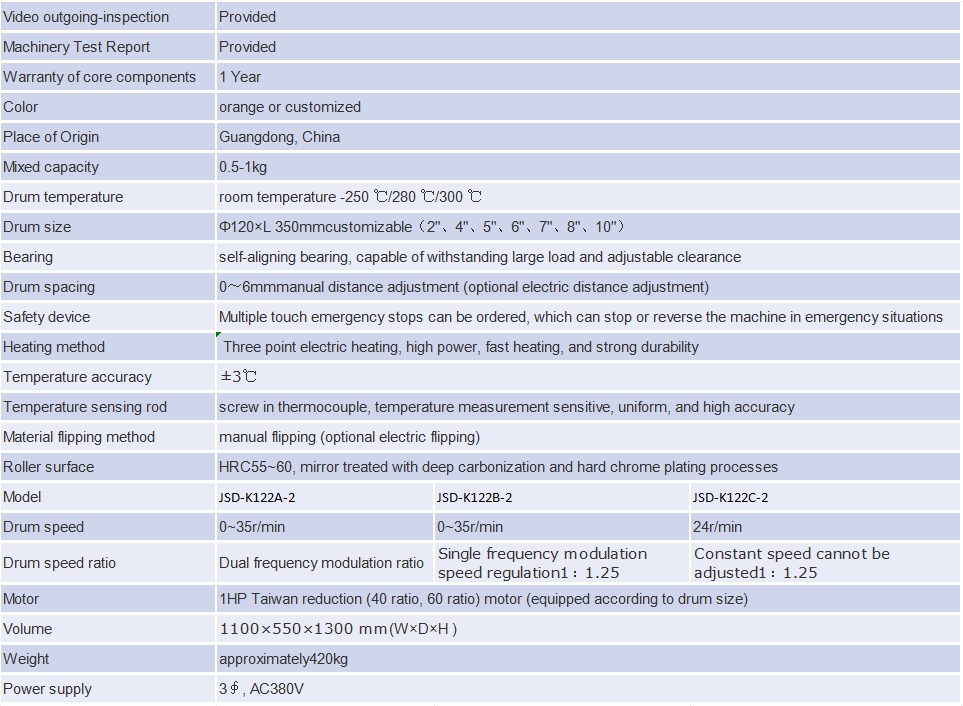

| Video outgoing-inspection | Provided | ||

| Machinery Test Report | Provided | ||

| Warranty of core components | 1 Year | ||

| Color | orange or customized | ||

| Place of Origin | Guangdong, China | ||

| Mixed capacity | 0.5-1kg | ||

| Drum temperature | room temperature -250 ℃/280 ℃/300 ℃ | ||

| Drum size | Φ120×L 350mmcustomizable(2"、4"、5"、6"、7"、8"、10") | ||

| Bearing | self-aligning bearing, capable of withstanding large load and adjustable clearance | ||

| Drum spacing | 0~6mmmanual distance adjustment (optional electric distance adjustment) | ||

| Safety device | Multiple touch emergency stops can be ordered, which can stop or reverse the machine in emergency situations | ||

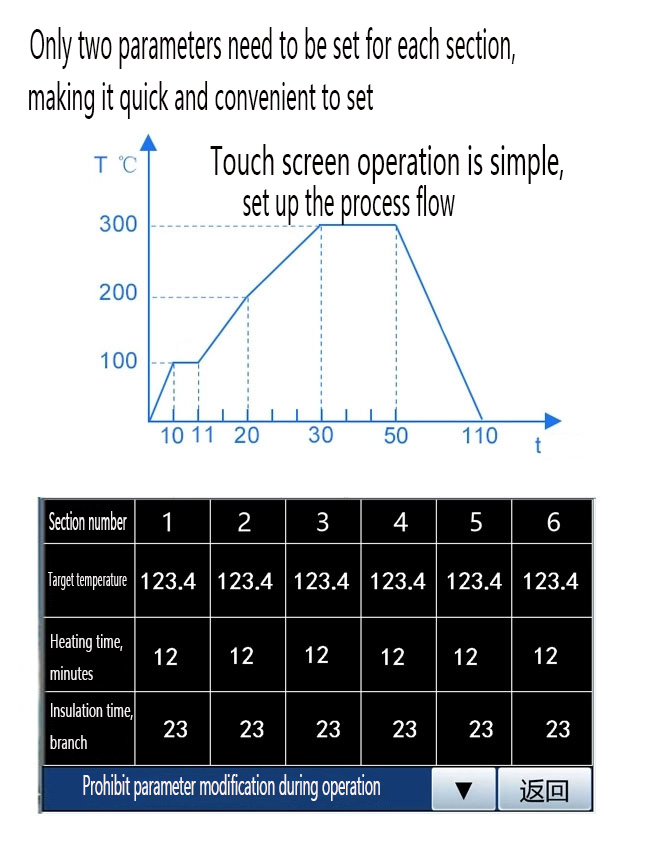

| Heating method | Three point electric heating, high power, fast heating, and strong durability | ||

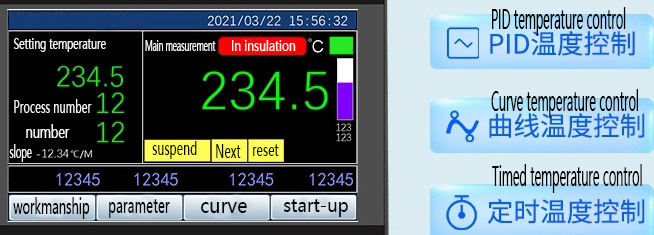

| Temperature accuracy |

±3℃,Touch screen digital temperature controller controls temperature |

||

| Temperature sensing rod | screw in thermocouple, temperature measurement sensitive, uniform, and high accuracy | ||

| Material flipping method | manual flipping (optional electric flipping) | ||

| Roller surface | HRC55~60, mirror treated with deep carbonization and hard chrome plating processes | ||

| Model | JSD-K122A-2 | JSD-K122B-2 | JSD-K122C-2 |

| Drum speed | 0~35r/min | 0~35r/min | 24r/min |

| Drum speed ratio | Dual frequency modulation ratio | Single frequency modulation speed regulation1:1.25 |

Constant speed cannot be adjusted 1:1.25 |

| Motor | 1HP Taiwan reduction (40 ratio, 60 ratio) motor (equipped according to drum size) | ||

| Volume | 1100×550×1300 mm(W×D×H ) | ||

| Weight | approximately420kg | ||

| Power supply | 3∮, AC380V | ||

Packaging and delivery

Supply Ability

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China