Visual milling cutter slitting machine

- Product Item : JSD-B070A-1

- Category: PCB slitting machine

- Multifunctional slitting machine

- PCB Splitting and Swinging Integrated Machine

- Saw blade slitting machine

- Silicone open mill

Suitable for composite PCB slitting connected to V-slots and stamp holes, especially for PCB slitting of parts crossing V-slots; Widely used in industries such as automobiles, power supplies, computers, home appliances, mobile phones, connectors, LEDs, etc

Suitable for composite PCB slitting connected to V-slots and stamp holes, especially for PCB slitting of parts crossing V-slots; Widely used in industries such as automobiles, power supplies, computers, home appliances, mobile phones, connectors, LEDs, etc

Online visual milling cutter slitting machine:

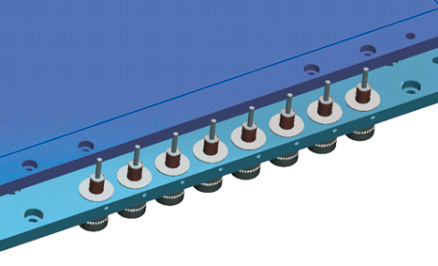

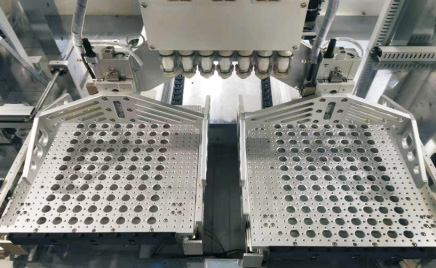

1. Dual platform stress free cutting

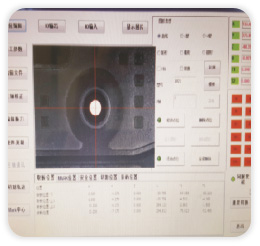

2. CCD vision, MARK point precise positioning, automatic correction

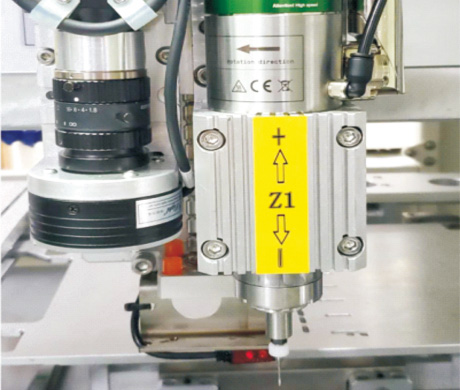

4. Automatic tool change spindle and system

5. Imported high-speed electric spindle

6. Fully automatic and unmanned dual platform efficient cutting

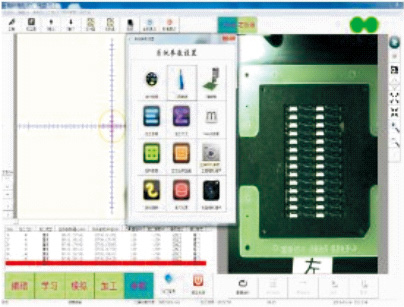

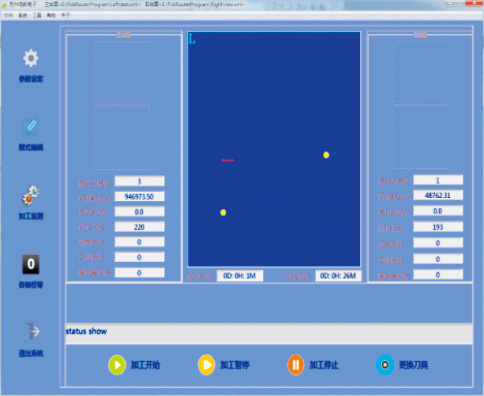

Online visual milling cutter slitting machine software system:

Windows/Linux systems,

Chinese English interface

Windows/Linux system, English and

Chinese operation interface

Easy and fast operation

Easy operation and easy to

understand

Accurate positioning and short programming time

Accurate positioning,

Due to the possibility of double-sided processing in your company's products, the standard MARK point is only on one side, so the correction action is indispensable

The Mark points used are usually irregular in shape and shape; Easy to encounter errors or compensation offset, based on previous experience

Our company has significantly improved the recognition pass rate and compensation accuracy by adopting intelligent camera upgrade algorithms and special light sources.

|

Automatic tool change: During processing, each step of inspection or each PCBA cut can be set for inspectionCheck if the tool is broken and prevent it from breaking during use in a timely manner Resulting in repeated cutting. |

Visual system: High pixel color digital camera and high magnification lens, capable of assisting programmingTeaching and editing simulation functions. Automatic MARK positioning auxiliary correction system. |

Product transfer platform: Dual platform modular servo control system with extremely high stabilityPerformance, cutting accuracy can reach ± 0.01mm, meeting various cutting needs Please ensure the quality of production. |

Mark positioning correction system:

1. Working mode: online

2. Number of workbenches: dual workbenches

3. Splitting area: 280 * 300MM

4. Control method: software+industrial computer+servo motor

5. Splitting speed: 0-100MM/S

6. Positioning accuracy:+0.01MM

7. Splitting speed:+0.02MM

8. Spindle speed: 60000~100000 RPM

9. Splitting thickness: 0-6mm

10. Vacuum suction method: up/down suction

11. Working pressure: 0.5~0.7 MPA

12. Working voltage: AC 380V 5KW

13. External dimensions: L1800 * W1500 * H2200mm

14. Weight: 865KG

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China