Non metallurgical tool splitting machine

- Product Item : JSD-B075A-1

- Category: PCB slitting machine

- Multifunctional slitting machine

- PCB Splitting and Swinging Integrated Machine

- Saw blade slitting machine

- Non metallurgical tool splitting machine

Suitable for composite PCB slitting connected to V-slots and stamp holes, especially for PCB slitting of parts crossing V-slots; Widely used in industries such as automobiles, power supplies, computers, home appliances, mobile phones, connectors, LEDs, etc

Characteristics of Online Non Metallurgical Splitting Machine:

1. This type of slitting machine is a fully automatic online cutting equipment that does not require manual intervention;

2. Equipped with a board computer or connected to customer testing (ATE) in the early stage to achieve board entry

3. The working principle is the same as the previous generation of offline products, both using high-speed spindles

4. Separate PCBA from the panel under low stress to ensure cutting accuracy and cleanliness

5. Automatic tool change and tool breakage detection

6. Fully automatic production mode

7. SPC statistical function and customer management system ERP integration

8. Optional explosion-proof vacuum cleaner and air volume monitoring function

|

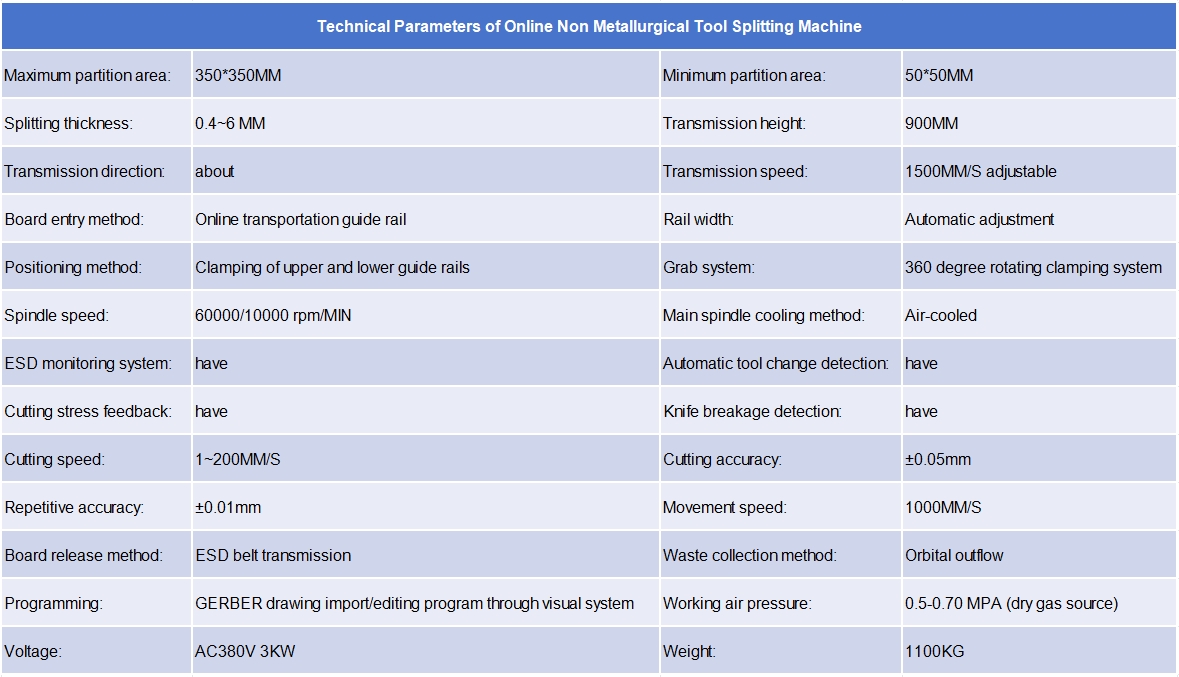

Technical Parameters of Online Non Metallurgical Tool Splitting Machine |

|||

|

Maximum partition area: |

350*350MM |

Minimum partition area: |

50*50MM |

|

Splitting thickness: |

0.4~6 MM |

Transmission height: |

900MM |

|

Transmission direction: |

about |

Transmission speed: |

1500MM/S adjustable |

|

Board entry method: |

Online transportation guide rail |

Rail width: |

Automatic adjustment |

|

Positioning method: |

Clamping of upper and lower guide rails |

Grab system: |

360 degree rotating clamping system |

|

Spindle speed: |

60000/10000 rpm/MIN |

Main spindle cooling method: |

Air-cooled |

|

ESD monitoring system: |

have |

Automatic tool change detection: |

have |

|

Cutting stress feedback: |

have |

Knife breakage detection: |

have |

|

Cutting speed: |

1~200MM/S |

Cutting accuracy: |

±0.05mm |

|

Repetitive accuracy: |

±0.01mm |

Movement speed: |

1000MM/S |

|

Board release method: |

ESD belt transmission |

Waste collection method: |

Orbital outflow |

|

Programming: |

GERBER drawing import/editing program through visual system |

Working air pressure: |

0.5-0.70 MPA (dry gas source) |

|

Voltage: |

AC380V 3KW |

Weight: |

1100KG |

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China