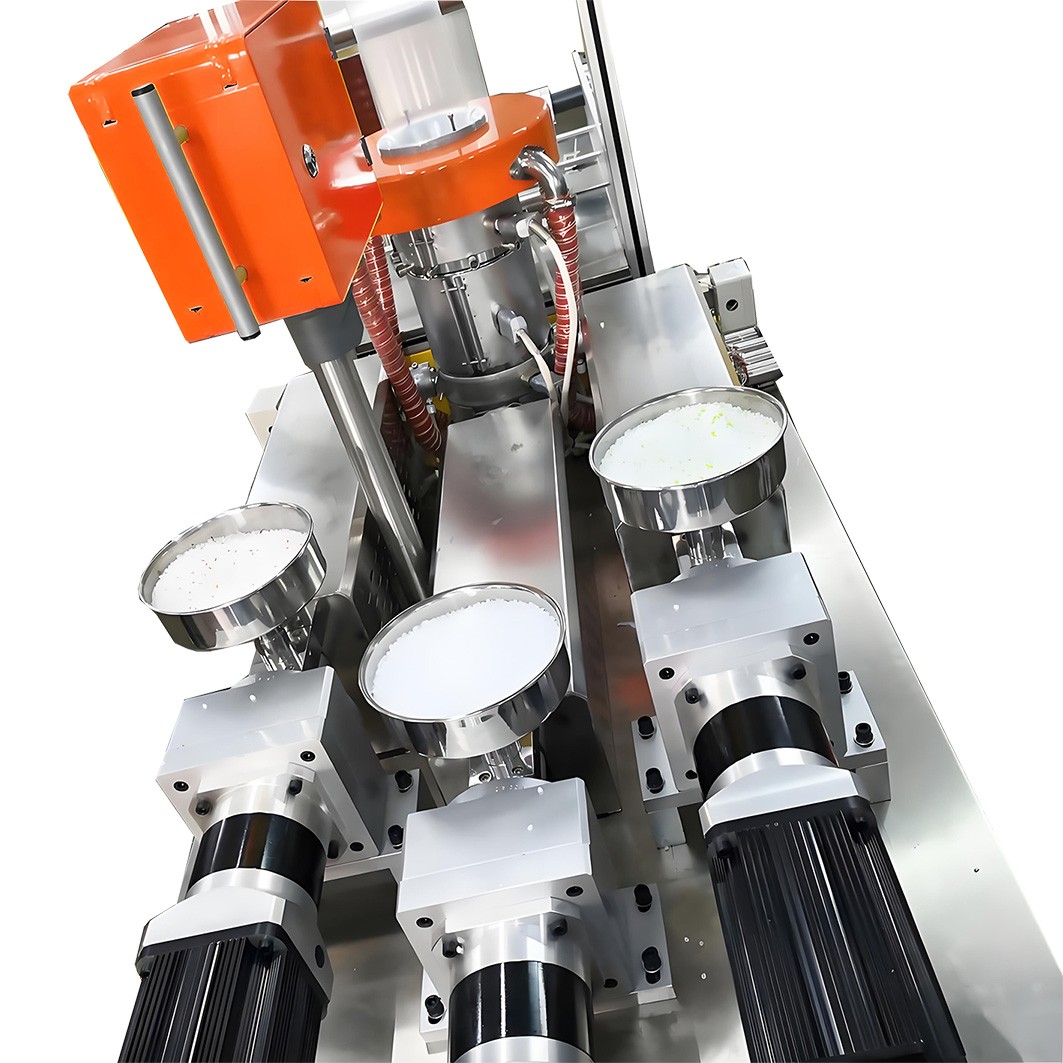

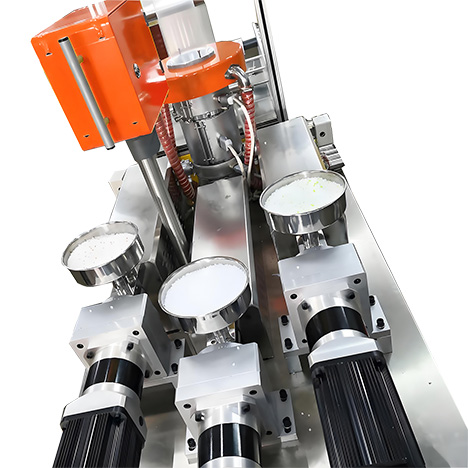

China machine PE Plastic Processed and Extrusion Blow Moulding Type ABC 3 Layer Multi-layer Film Blowing Machine

- Product Item : JSD-C042A-1

- Category: Blowing film machine

- Three layer co extrusion blown film machine

- PLA film blowing machine

- PBAT film blowing machine

- high and low pressure polyethylene film blowing machine

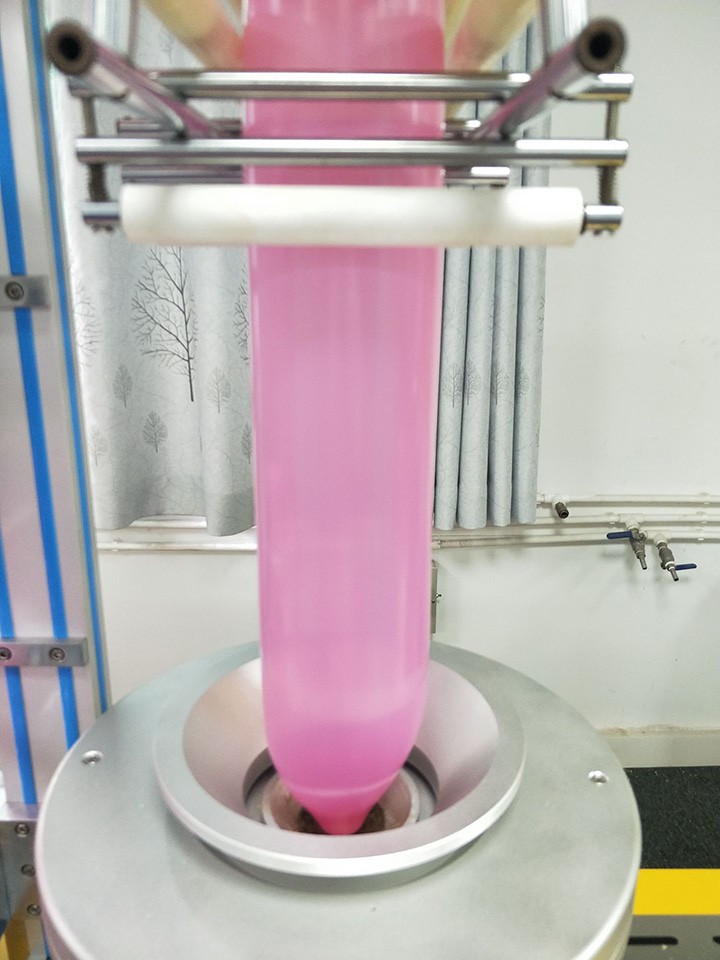

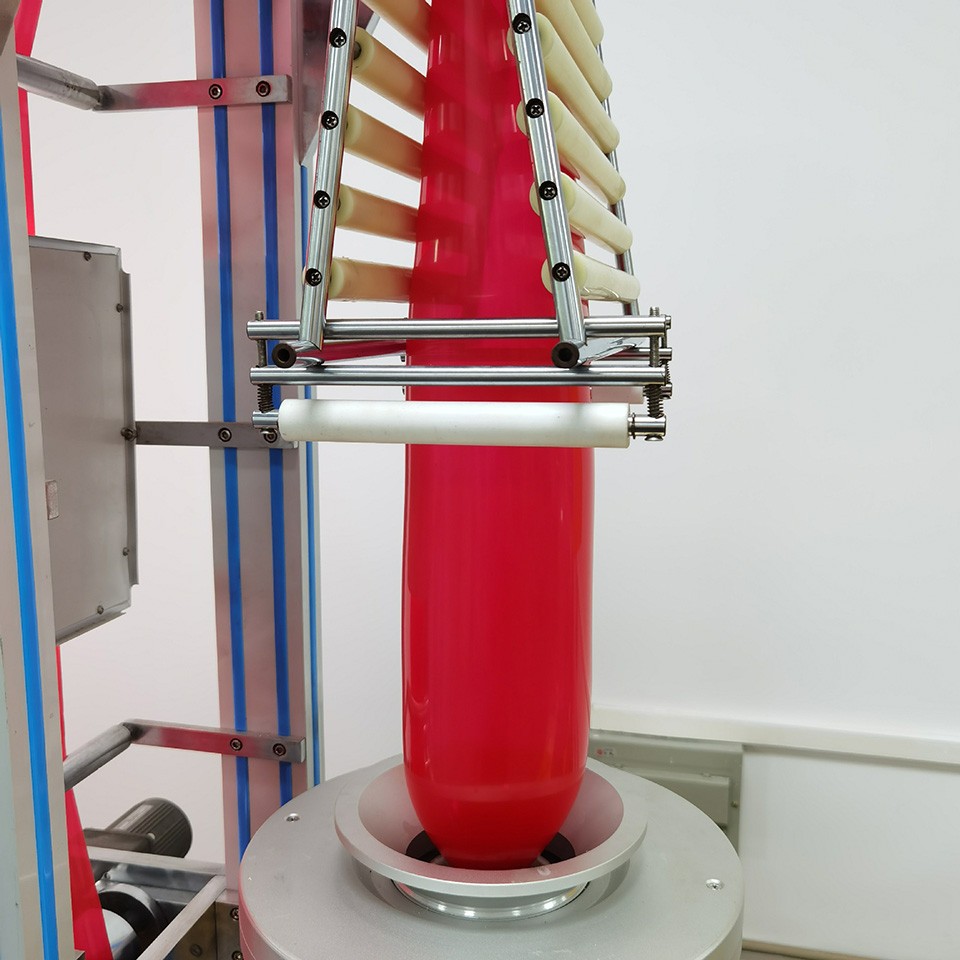

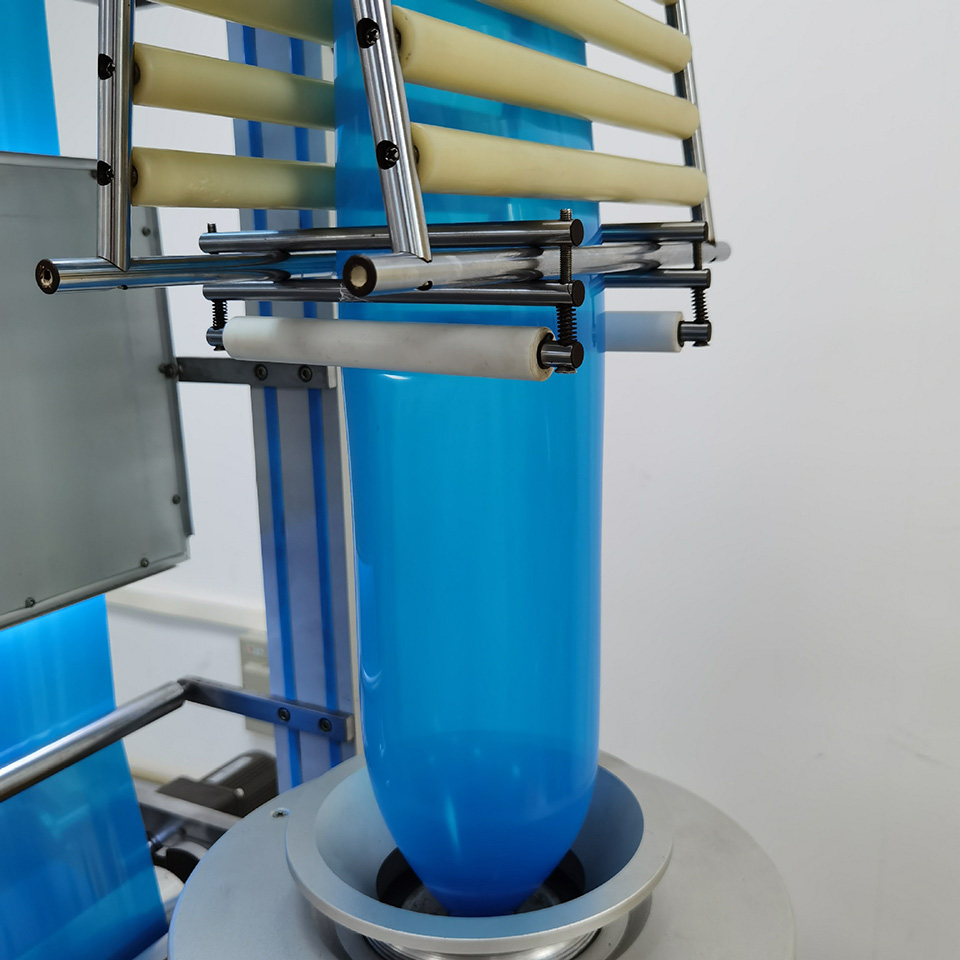

Three layer extrusion blown film is a process in which the plastic melt is continuously extruded through the mold under a certain shear force through a single screw conveyor at the processing temperature of the raw material. It is then blown by compressed air, cooled by a wind ring, and pulled by a frequency converter to obtain a double diameter plastic film. Mainly used to detect the feasibility of blowing film on polymer materials and the gum condition inside the materials, as well as the dispersion of colored dispersions, control mixtures, and extrudates

Key attributes

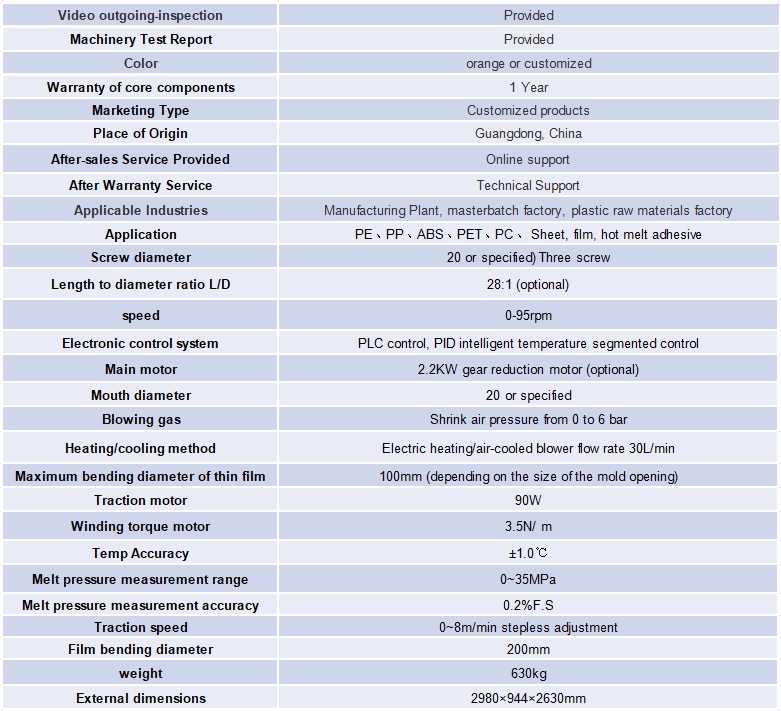

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Color | orange or customized |

| Warranty of core components | 1 Year |

| Marketing Type | Customized products |

| Place of Origin | Guangdong, China |

| After-sales Service Provided | Online support |

| After Warranty Service | Technical Support |

| Applicable Industries | Manufacturing Plant, masterbatch factory, plastic raw materials factory |

| Application | PE、PP、ABS、PET、PC、 Sheet, film, hot melt adhesive |

| Screw diameter | 20 or specified) Three screw |

| Length to diameter ratio L/D | 28:1 (optional) |

| speed | 0-95rpm |

| Electronic control system | PLC control, PID intelligent temperature segmented control |

| Main motor | 2.2KW gear reduction motor (optional) |

| Mouth diameter | 20 or specified |

| Blowing gas | Shrink air pressure from 0 to 6 bar |

| Heating/cooling method | Electric heating/air-cooled blower flow rate 30L/min |

| Maximum bending diameter of thin film | 100mm (depending on the size of the mold opening) |

| Traction motor | 90W |

| Winding torque motor | 3.5N/ m |

| Temp Accuracy | ±1.0℃ |

| Melt pressure measurement range | 0~35MPa |

| Melt pressure measurement accuracy | 0.2%F.S |

| Traction speed | 0~8m/min stepless adjustment |

| Film bending diameter | 200mm |

| weight | 630kg |

| External dimensions | 2980×944×2630mm |

Packaging and delivery

Supply Ability

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China