PCB Splitting and Swinging Integrated Machine

- Product Item : JSD-B011A-1

- Category: PCB slitting machine

- Multifunctional slitting machine

- PCB Splitting and Swinging Integrated Machine

- PVC open mill

- Silicone open mill

Suitable for composite PCB slitting connected to V-slots and stamp holes, especially for PCB slitting of parts crossing V-slots; Widely used in industries such as automobiles, power supplies, computers, home appliances, mobile phones, connectors, LEDs, etc

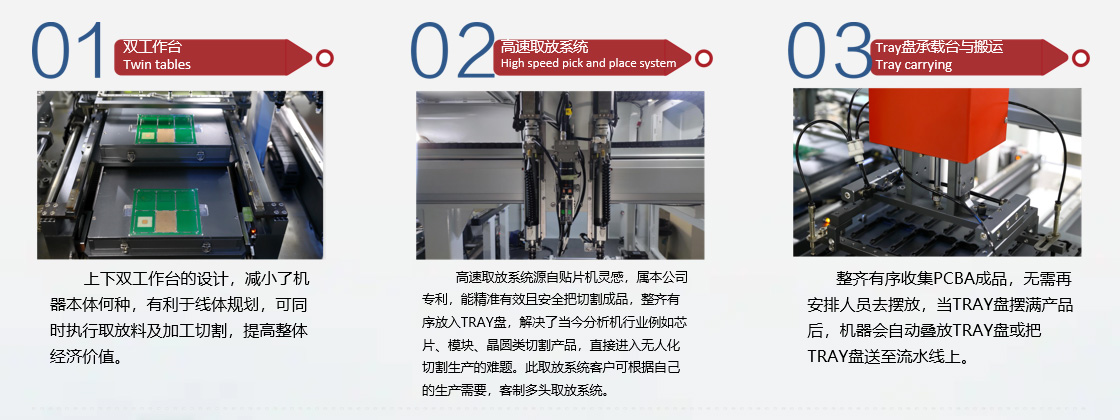

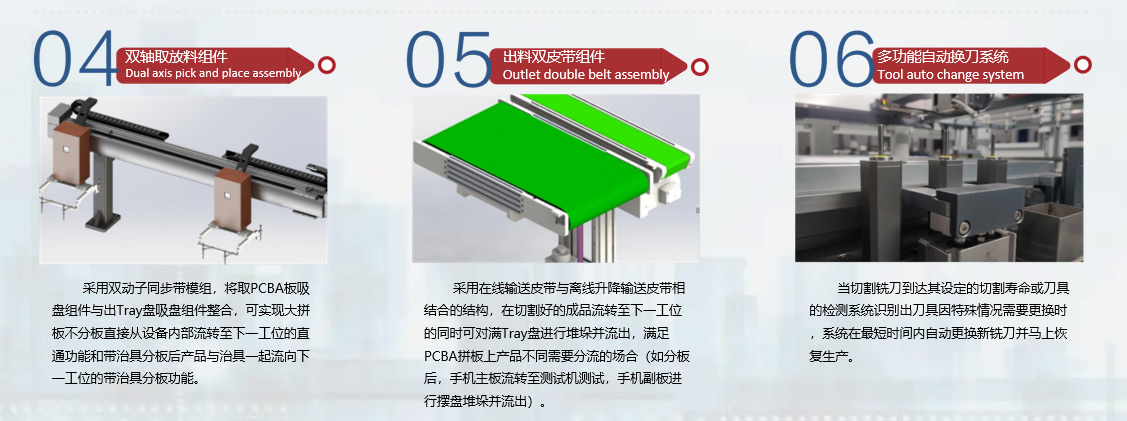

Features of the Online Splitting and Swinging Integrated Machine:

1. Dual worktable splitting and multi head swing plate

2. Vacuum assisted fixed PCB board (optional)

3. Milling cutter lifespan and tool breakage detection

4. Automatic tool change and segmented cutting

5. Automatic placement of cut finished products

6. Tray tray automatic retrieval/placement

7. Anti static high-speed spindle

8. High precision and good stability in board positioning

9. Automatic replacement of splitting fixtures

10. Automatic CCD detection of cutting position (optional)

11. Automatic scanning of PCB QR code (optional)

12. Up and down vacuum cleaners can be freely switched

13. Automatic X-board removal through MES system (optional)

14. Multi functional offline programming system

15. Large board through, small board swing

16. Loading and unloading with fixtures

17. Adapted to high-frequency machine line changing, solving the problem of long line changing time for online circuit breakers in the industry today

Technical parameters of online splitting and swinging integrated machine:

1. Control system: X, Y, Z&R axes

2. Motion axis: 16 axis feed X; Take board X; Milling cutter X/Y/Z; Vehicles Y1/Y2; High speed material retrieval X/Z1/Z2/R1/R2; Tray conveyor line Y; Take Tray X; Discharge belt X/Z

3. Control motor: AC servo

4. Positioning accuracy:+0.01MM

5. Workstation: dual upper and lower workstations

6. Transmission direction: from left to right

7. PCB fixing reinforcement (optional): Vacuum assisted PCB board

8. PCB handling: vacuum material handling arm

9. Splitting area: 280mm X 230mm (other specifications can be customized)

10. Splitting thickness: 0.5-6MM

11. Splitting accuracy: 0.02MM

12. Spindle: High speed anti-static 100000 RPM with automatic tool change system

13. Milling cutter specifications: 0.8-3.0MM

14. Knife breakage detection: supported

15. Vacuum Cleaning System: Vacuum Cleaning 5HP Lower Vacuum Cleaning/Lower Vacuum Cleaning

16. Operating system: Windows 10

17. Programming: Online programming/10x CCD camera or scanning full image graphical programming/offline programming

18. Weight: 1400KG

19. External dimensions: 1950 (L) X1550 (W) X1600 (H) mm

20. Power supply requirement: 3-phase AC380V 50HZ 13KW

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China