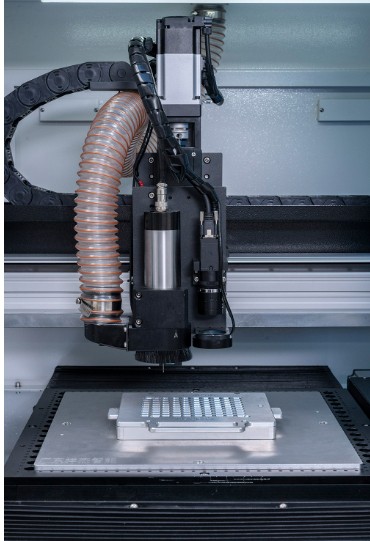

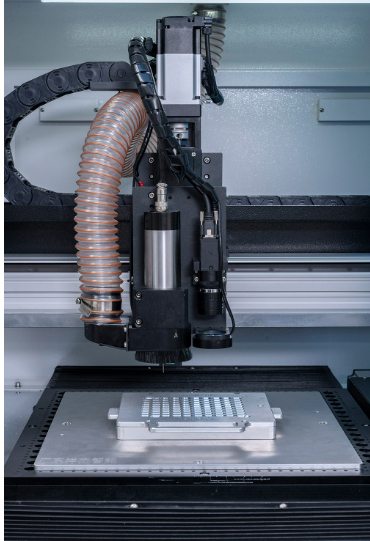

Single station visual milling cutter slitting machine

- Product Item : JSD-B040A-1

- Category: PCB slitting machine

- Composite Splitting Machine

- PCB Splitting and Swinging Integrated Machine

- Saw blade slitting machine

- Non metallurgical tool splitting machine

Suitable for cutting PCB stamp holes, curved PCBs, and irregular PCBs. Widely used in industries such as automobiles, power supplies, computers, home appliances, mobile phones, connectors, LEDs, etc.

Features of Single Station Visual Milling Knife Splitting Machine:

The landing single platform three-axis servo drive is a device that separates multiple connected PCBs according to pre programmed paths, replacing manual breaking or V-CUT or PUSH cutting defects and stress damage, improving product quality and reducing scrap rates. This machine adopts a human-machine interface, AC servo motor, and WIN7 system operation interface. The cutting path is taught and edited by a high pixel CCD production program, and can be modified and simulated in a single step, resulting in higher production efficiency and quality. The software is equipped with MAKE compensation, with large, medium, and small three windows for more accurate programming. A rectangular box is added on the basis of the original target, making programming more intuitive and achieving precise programming. The MAKE geometric alignment is automatically grasped, with faster response, more independent parameters, higher efficiency, and more guaranteed cutting accuracy.

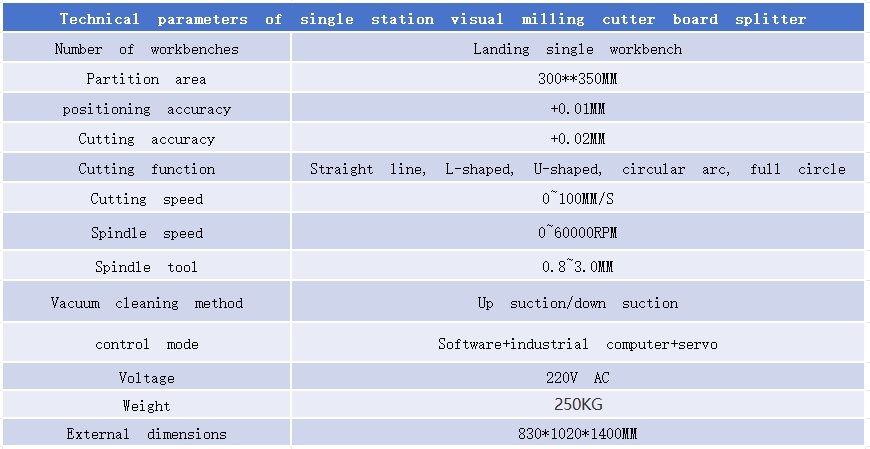

| Technical parameters of single station visual milling cutter board splitter | |

| Number of workbenches | Landing single workbench |

| Partition area | 300**350MM |

| positioning accuracy | +0.01MM |

| Cutting accuracy | +0.02MM |

| Cutting function | Straight line, L-shaped, U-shaped, circular arc, full circle |

| Cutting speed | 0~100MM/S |

| Spindle speed | 0~60000RPM |

| Spindle tool | 0.8~3.0MM |

| Vacuum cleaning method | Up suction/down suction |

| control mode | Software+industrial computer+servo |

| Voltage | 220V AC |

| Weight | 250KG |

| External dimensions | 830*1020*1400MM |

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China