Thin film material laser cutting machine

- Product Item : JSD-G6050R-2

- Category: Laser equipment

- Multipurpose laser cutting machine

- Small face picosecond laser cutting machine

- Thin film material laser cutting machine

- Non metallurgical tool splitting machine

Laser cutting machines for thin film materials are mainly used for cutting thin film materials, covering various types of thin films such as roll to roll, PET film, PI film, PP film, adhesive film, copper foil, explosion-proof film, electromagnetic film, Sony adhesive, etc.

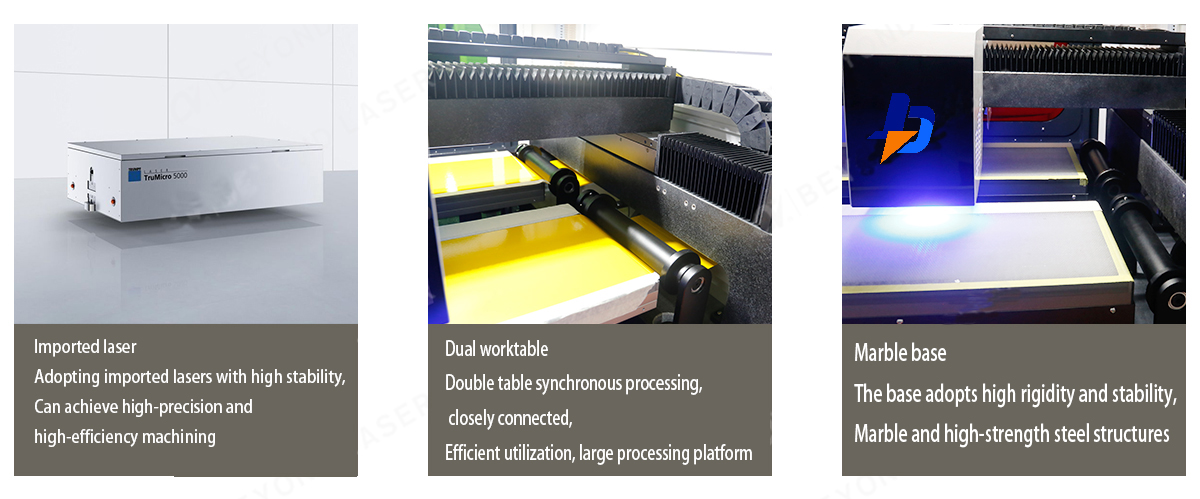

High precision: comprehensive machining accuracy ± 25 µ m

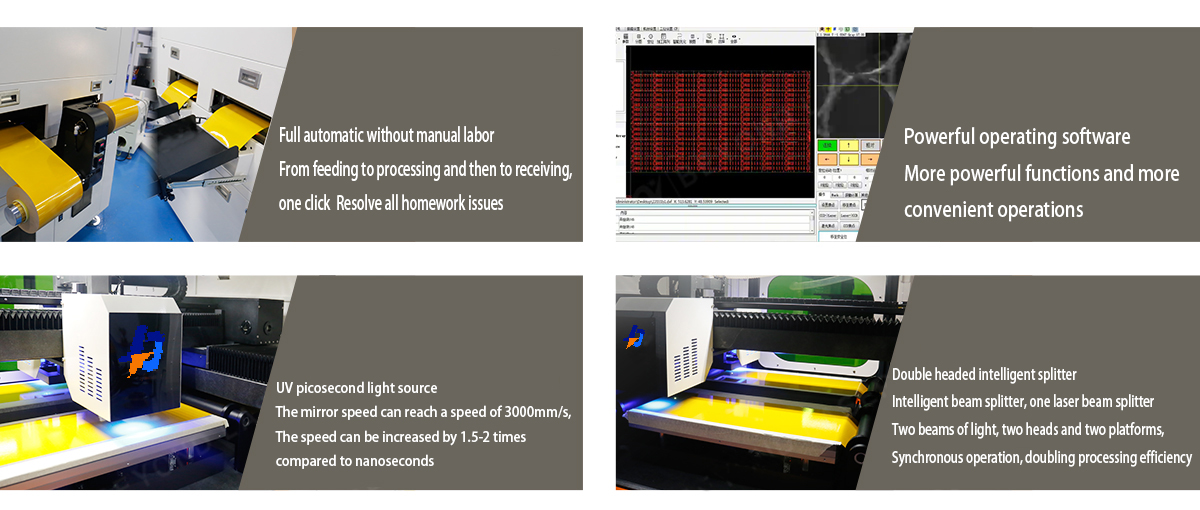

Fast speed: cutting efficiency can reach up to 7000mm/s

Low cost: From feeding to processing to receiving, one click solution to all operational problems, saving labor costs

Efficient: Equipped with dual workbenches, the work efficiency is twice as enjoyable.

Customizable non-standard laser cutting to achieve automated production.

|

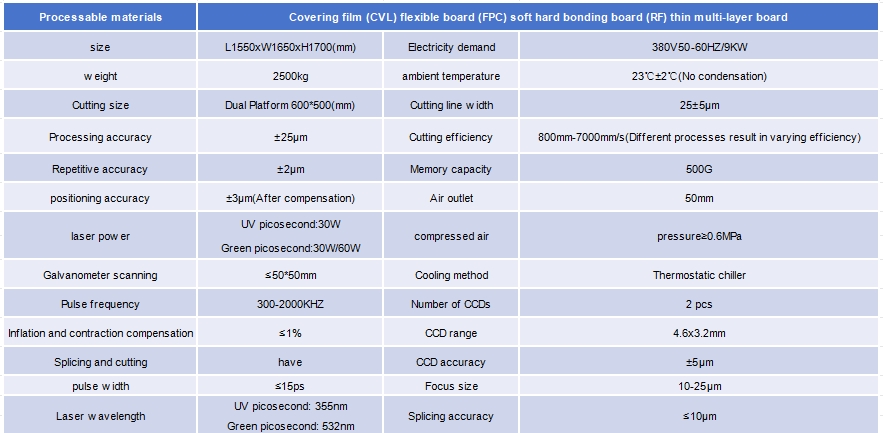

Processable materials |

Covering film (CVL) flexible board (FPC) soft hard bonding board (RF) thin multi-layer board |

||

|

size |

L1550xW1650xH1700(mm) |

Electricity demand |

380V50-60HZ/9KW |

|

weight |

2500kg |

ambient temperature |

23℃±2℃(No condensation) |

|

Cutting size |

Dual Platform 600*500(mm) |

Cutting line width |

25±5μm |

|

Processing accuracy |

±25µm |

Cutting efficiency |

800mm-7000mm/s(Different processes result in varying efficiency) |

|

Repetitive accuracy |

±2μm |

Memory capacity |

500G |

|

positioning accuracy |

±3µm(After compensation) |

Air outlet |

50mm |

|

laser power |

UV picosecond:30W Green picosecond:30W/60W |

compressed air |

pressure≥0.6MPa |

|

Galvanometer scanning |

≤50*50mm |

Cooling method |

Thermostatic chiller |

|

Pulse frequency |

300-2000KHZ |

Number of CCDs |

2 pcs |

|

Inflation and contraction compensation |

≤1% |

CCD range |

4.6x3.2mm |

|

Splicing and cutting |

have |

CCD accuracy |

±5μm |

|

pulse width |

≤15ps |

Focus size |

10-25μm |

|

Laser wavelength |

UV picosecond: 355nm Green picosecond: 532nm |

Splicing accuracy |

≤10μm |

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China