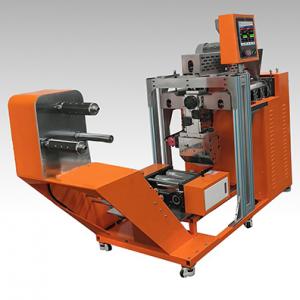

China Manufacturer's Rubber Compound Two-Roll Mill Open Mixing Mill for Efficient Rubber Processing

- Product Item : JSD-K230A-1

- Category: Two Roll Mill

- Rubber silicone Two-Roll Mill

- 9-inch Two-Roll Mill

- PVC Two-Roll Mill

- Silicone Two-Roll Mill

The rubber silicone open mill is suitable for the mixing and processing of chemical raw materials such as rubber and silicone. Fill the drum with water, rotate the drum, mix the rubber and compounding agent evenly, and produce the film. Used for small-scale production or testing to achieve the required color and quality of products.

1,Upgraded spacing display to digital display

2,Upgraded material blocking adjustment (optional automatic)

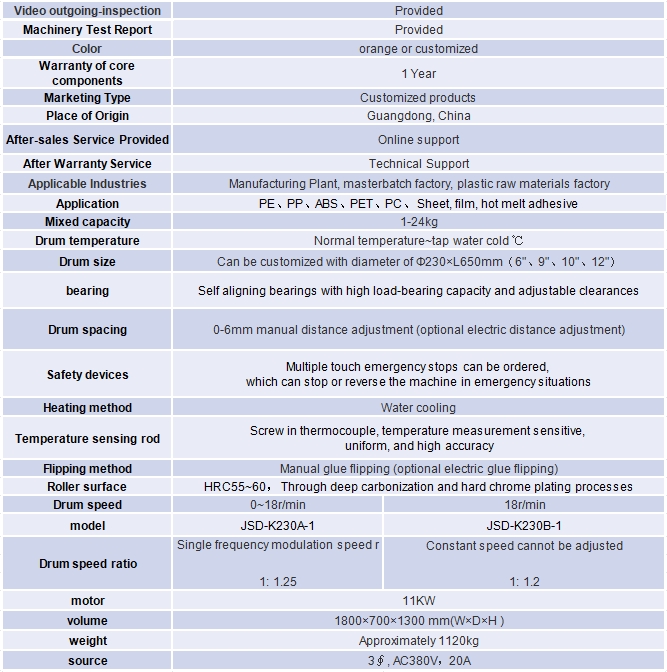

Key attributes

| Video outgoing-inspection | Provided | |

| Machinery Test Report | Provided | |

| Color | orange or customized | |

| Warranty of core components | 1 Year | |

| Marketing Type | Customized products | |

| Place of Origin | Guangdong, China | |

| After-sales Service Provided | Online support | |

| After Warranty Service | Technical Support | |

| Applicable Industries | Manufacturing Plant, masterbatch factory, plastic raw materials factory | |

| Application | PE、PP、ABS、PET、PC、 Sheet, film, hot melt adhesive | |

| Mixed capacity | 1-24kg | |

| Drum temperature | Normal temperature~tap water cold ℃ | |

| Drum size | Can be customized with diameter of Φ230×L650mm(6"、9"、10"、12") | |

| bearing | Self aligning bearings with high load-bearing capacity and adjustable clearances | |

| Drum spacing | 0-6mm manual distance adjustment (optional electric distance adjustment) | |

| Safety devices |

Multiple touch emergency stops can be ordered,

which can stop or reverse the machine in emergency situations

|

|

| Heating method | Water cooling | |

| Temperature sensing rod |

Screw in thermocouple, temperature measurement sensitive,

uniform, and high accuracy

|

|

| Flipping method | Manual glue flipping (optional electric glue flipping) | |

| Roller surface | HRC55~60, Through deep carbonization and hard chrome plating processes | |

| Drum speed | 0~18r/min | 18r/min |

| model | JSD-K230A-1 | JSD-K230B-1 |

| Drum speed ratio | Single frequency modulation speed regulation | Constant speed cannot be adjusted |

| 1: 1.25 | 1: 1.2 | |

| motor | 11KW | |

| volume | 1800×700×1300 mm(W×D×H ) | |

| weight | Approximately 1120kg | |

| source | 3∮, AC380V,20A | |

Packaging and delivery

Packaging Details

Wooden case

Supply Ability

Supply Ability

25 Set/Sets per Month

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China