Customized JSD-Y202A-1 Automatic Two Roller Thermal Silicone Calender Automatic Manufacturers Direct Supply Embossing Machine China machine

- Product Item : JSD-Y202A-1

- Category: Rolling machine

- Thermal silicon rolling machine

- Thermal conductive silicone calender

- silicone rubber rolling machine

- Thermal conductive silicone rolling lamination machine

Usage: Suitable for various liquid and semi-solid thermal conductive silicone gaskets

The substrate feeding section adopts three feeding shafts, all equipped with electromagnetic magnetic powder tension controllers and tile type air curtain shafts. Fully meet the requirements of customers for upper and lower PET, intermediate fiberglass, and thick material edge blocking sponge.

The thickness rolling section uses precision rolling rods to roll the material, which is completed through multiple processes such as heat treatment, precision grinding, electroplating, etc. The finished product accuracy can reach 0.2 ± 0.015

The transmission part adopts a combination transmission gear (patented part) designed by Senjie Company, which has high torque and stable transmission operation. The maximum distance between the two rods is 12mm.

The inspection part of the discharge port adopts a PED lamp folding light box and a micrometer inspection port

Technical description of tunnel oven:

1. Specifications: The overall length of the furnace frame is 13 meters, the width is 0.9 meters, and the height (from the ground to the conveyor belt working surface) is adjustable from 0.7 to 0.8 meters; The dimensions inside the furnace body are 6 meters long, 0.8 meters wide, and 0.2 meters high; Divide into 3 sections of 2 meters each;

2. Furnace frame section: The main line is made of 40 * 80 * 3mm iron square pipes, with machine feet arranged in groups of 2 meters each;

3. Furnace body: ⑴ The exterior is coated with 1.5 cold plate paint, and the inner liner is made of 10mm high-temperature tempered glass, ensuring that there will be no self explosion or self cracking within the adjustable temperature range; ⑵ Insulation: Use 80K rock wool to make an insulation layer with a thickness of 80mm;

4. Mechanical and Electrical/Operation Section: ⑴ The entire furnace is divided into 3 sections, each section is 2 meters long, and each section is independently electrically controlled and can be segmented for temperature adjustment (50-220 ℃ adjustable); ⑵ Details of each section of electrical control device: Taiwan made BKC digital temperature control meter, Delixi AC contactor, voltmeter, ammeter, indicator switch, over temperature protection and alarm device; All electronic control devices are centrally located at the machine head for easy operation Heating element: made of quartz tube, 380V/24KW. (4) Air supply section: segmented air supply, using 0.5HP high-efficiency motor with 7.5 "wind wheel for each section, a total of 3 sets; (5) Conveyor belt: Equipped with 0.8mm PTFE belt and front and rear main drive rollers, equipped with adjustable elastic shafts at the front and rear Conveyor belt power device: 1HP frequency converter, 1HP marine transmission motor, 1:60-80 reducer.

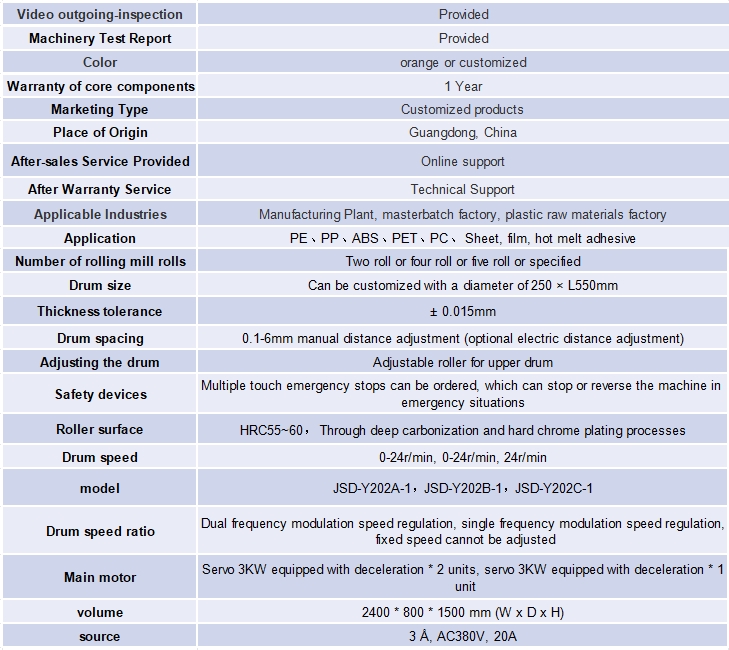

Key attributes

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Color | orange or customized |

| Warranty of core components | 1 Year |

| Marketing Type | Customized products |

| Place of Origin | Guangdong, China |

| After-sales Service Provided | Online support |

| After Warranty Service | Technical Support |

| Applicable Industries | Manufacturing Plant, masterbatch factory, plastic raw materials factory |

| Application | PE、PP、ABS、PET、PC、 Sheet, film, hot melt adhesive |

| Number of rolling mill rolls | Two roll or four roll or five roll or specified |

| Drum size | Can be customized with a diameter of 250 × L550mm |

| Thickness tolerance | ± 0.015mm |

| Drum spacing | 0.1-6mm manual distance adjustment (optional electric distance adjustment) |

| Adjusting the drum | Adjustable roller for upper drum |

| Safety devices | Multiple touch emergency stops can be ordered, which can stop or reverse the machine in emergency situations |

| Roller surface | HRC55~60, Through deep carbonization and hard chrome plating processes |

| Drum speed | 0-24r/min, 0-24r/min, 24r/min |

| model | JSD-Y202A-1,JSD-Y202B-1,JSD-Y202C-1 |

| Drum speed ratio | Dual frequency modulation speed regulation, single frequency modulation speed regulation, fixed speed cannot be adjusted |

| Main motor | Servo 3KW equipped with deceleration * 2 units, servo 3KW equipped with deceleration * 1 unit |

| volume | 2400 * 800 * 1500 mm (W x D x H) |

| source | 3 Å, AC380V, 20A |

Packaging and delivery

Supply Ability

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China