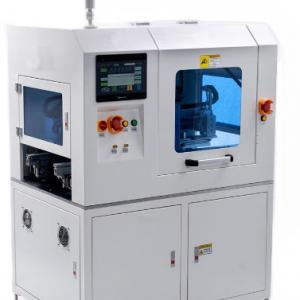

High quality CE certification CF-1L MIM kneader mixer machine for metallurgy metal / ceramic powder internal mixerMIM ceramic powder mixer China machine

- Product Item : JSD-M007A-1

- Category: Internal mixer

- Small internal mixer

- Experimental mixer

- Dust proof internal mixer

- electric heating internal mixer

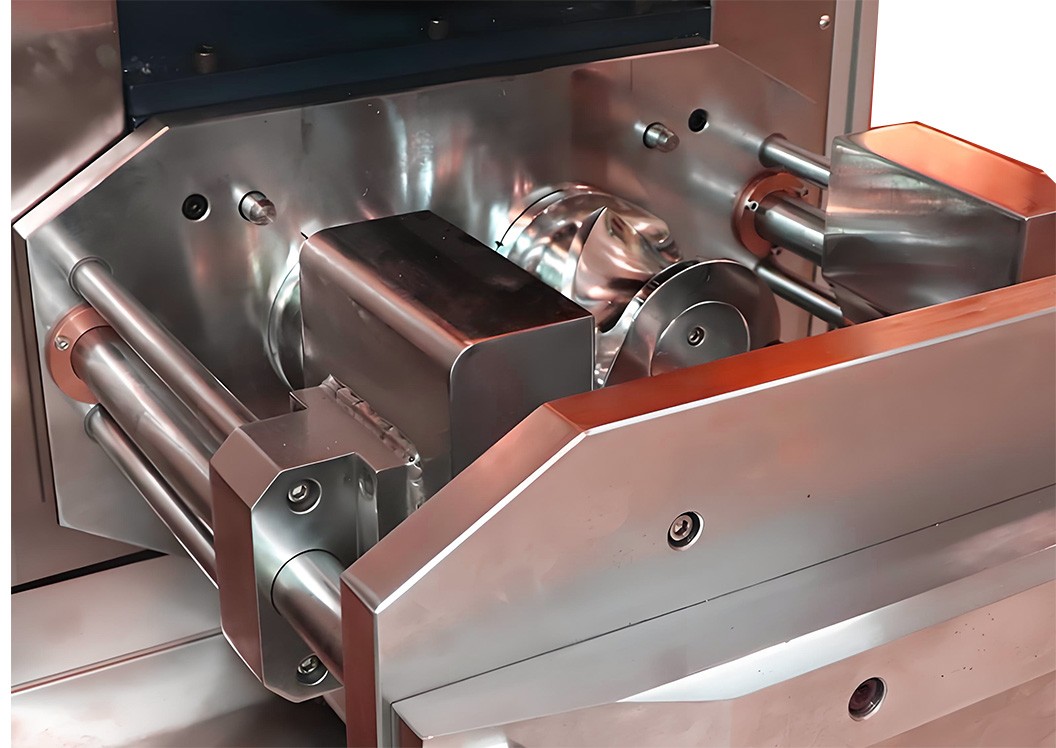

The MIM mixer is specifically designed for mixing metal powders. Suitable for mixing metal powders such as ceramic powder, stainless steel, aluminum alloy, titanium alloy, etc. After customer verification, ordinary internal mixers can mix iron powder, metal powder, and materials, resulting in rapid rotor wear. MIM mixer, processed by material, alloy ion spraying or welding, greatly improves the lifespan of the rotor and mixing chamber in mixing high-strength materials.

1: Technical advantages of MIM mixer

1: Excellent dispersion effect optimizes the technical parameters of the rotor, upper and lower top bolts in the mixing system, ensuring uniform material mixing and achieving good results in year-on-year mixing with changes in physical properties.

A. The rotor blades are welded with imported alloy steel to ensure safety; The rotor shaft is treated with 38CrMoALA nitrided HV950-1050, with a depth of 0.6-0.75mm and brittleness not exceeding level 11, to ensure high hardness, high load-bearing capacity, strong torque, continuous shaft operation, and smooth transmission of the rotor shaft.

B. All surfaces in contact with materials are sprayed with tungsten carbide:

New generation Open-close type kneader, it is an innovation in kneading equipment. For this equipment, the both ends of the rotor is the separating surface, and with oil pressure system to lock automatically, the roller is easy to take out. It is broken from tradition for mixing machine that difficult to clean, color changing, and repair it is controlled by PLC software, to make the process more simplified and easy to control in continuous production process.

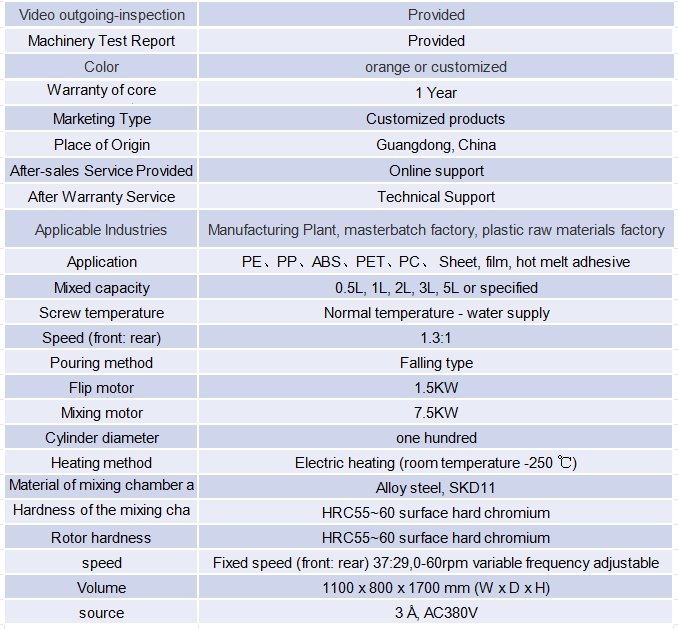

Key attributes

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Color | orange or customized |

| Warranty of core components | 1 Year |

| Marketing Type | Customized products |

| Place of Origin | Guangdong, China |

| After-sales Service Provided | Online support |

| After Warranty Service | Technical Support |

| Applicable Industries | Manufacturing Plant, masterbatch factory, plastic raw materials factory |

| Application | PE、PP、ABS、PET、PC、 Sheet, film, hot melt adhesive |

| Mixed capacity | 0.5L, 1L, 2L, 3L, 5L or specified |

| Screw temperature | Normal temperature - water supply |

| Speed (front: rear) | 1.3:1 |

| Pouring method | Falling type |

| Flip motor | 1.5KW |

| Mixing motor | 7.5KW |

| Cylinder diameter | one hundred |

| Heating method | Electric heating (room temperature -250 ℃) |

| Material of mixing chamber and rotor | Alloy steel, SKD11 |

| Hardness of the mixing chamber | HRC55~60 surface hard chromium |

| Rotor hardness | HRC55~60 surface hard chromium |

| speed | Fixed speed (front: rear) 37:29,0-60rpm variable frequency adjustable |

| Volume | 1100 x 800 x 1700 mm (W x D x H) |

| source | 3 Å, AC380V |

Packaging and delivery

Supply Ability

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China