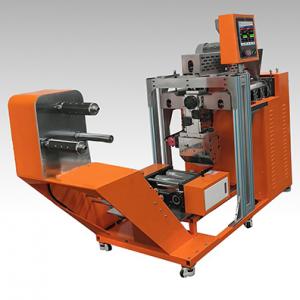

Atmosphere-protected mixers and compactors for mixing and dispersing titanium alloys, copper alloys, aluminum alloys, tungsten alloys .Atmosphere protection mixer China machine

- Product Item : JSD-M008A-1

- Category: Internal mixer

- Atmosphere protection mixer

- Experimental mixer

- Dust proof internal mixer

- electric heating internal mixer

The atmosphere protection experimental mixer is mainly used for mixing and dispersing experiments of materials such as titanium alloy, copper alloy, aluminum alloy, tungsten alloy, etc. A small volume of 1L ensures that the experiment is completed with the least amount of material, avoiding material waste. Using imported oxygen content detection instruments to ensure accurate numerical values; The whole machine adopts multiple sealing devices to ensure no air leakage and can complete the experiment with the minimum amount of air used.

The mixing chamber and rotor are made of new alloy steel materials, which undergo special vacuum heat treatment, CNC machining, and surface mirror polishing treatment, ultimately achieving overall steel wear resistance and corrosion resistance (salt corrosion, acid corrosion, alkali corrosion, hydrogen sulfide corrosion, and other types of corrosion).

Servo coaxial separation technology is used for easy color and material replacement. It can be separated with one end face of the rotor as the axis, breaking the bottleneck of traditional internal mixers. The open and close internal mixers control unnecessary economic losses caused by material pollution. At the same time as the mixing room is opened and closed, the rotor is suspended in the middle, making it easy to clean and change materials. The rotor is detachable, and the staff can clean any part, providing a comprehensive design.

Vacuum pumping can quickly remove most of the air, greatly reducing the inflation time.

Inert gas introduction (nitrogen or argon), users can set the upper and lower limits of oxygen content, and the equipment automatically starts and closes the inert gas switch, greatly saving gas consumption.

Equipped with upper computer software, it can connect to the computer for real-time monitoring, record and save, and export data

Protection against high concentration gas shock and sensor fault self-test function

D: Detection accuracy: ≤ ± 3% (F.S) E: Zero drift: ≤ ± 1% (F.S/year) F: Linear error: ≤ ± 1%

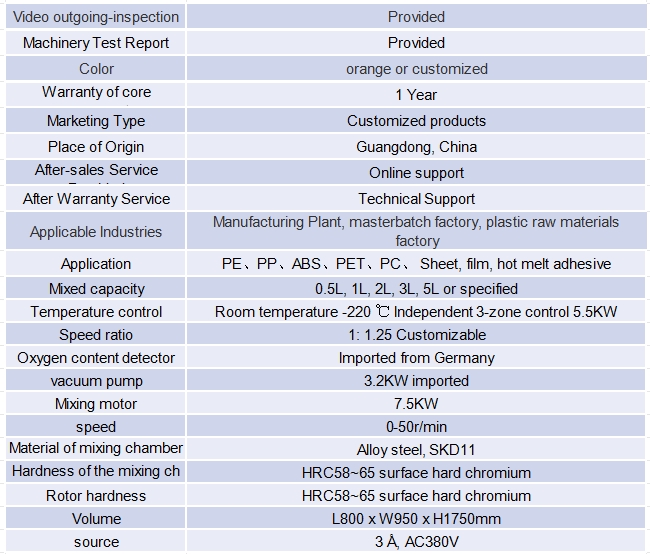

Key attributes

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Color | orange or customized |

| Warranty of core components | 1 Year |

| Marketing Type | Customized products |

| Place of Origin | Guangdong, China |

| After-sales Service Provided | Online support |

| After Warranty Service | Technical Support |

| Applicable Industries | Manufacturing Plant, masterbatch factory, plastic raw materials factory |

| Application | PE、PP、ABS、PET、PC、 Sheet, film, hot melt adhesive |

| Mixed capacity | 0.5L, 1L, 2L, 3L, 5L or specified |

| Temperature control | Room temperature -220 ℃ Independent 3-zone control 5.5KW |

| Speed ratio | 1: 1.25 Customizable |

| Oxygen content detector | Imported from Germany |

| vacuum pump | 3.2KW imported |

| Mixing motor | 7.5KW |

| speed | 0-50r/min |

| Material of mixing chamber and rotor | Alloy steel, SKD11 |

| Hardness of the mixing chamber | HRC58~65 surface hard chromium |

| Rotor hardness | HRC58~65 surface hard chromium |

| Volume | L800 x W950 x H1750mm |

| source | 3 Å, AC380V |

Packaging and delivery

Supply Ability

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China