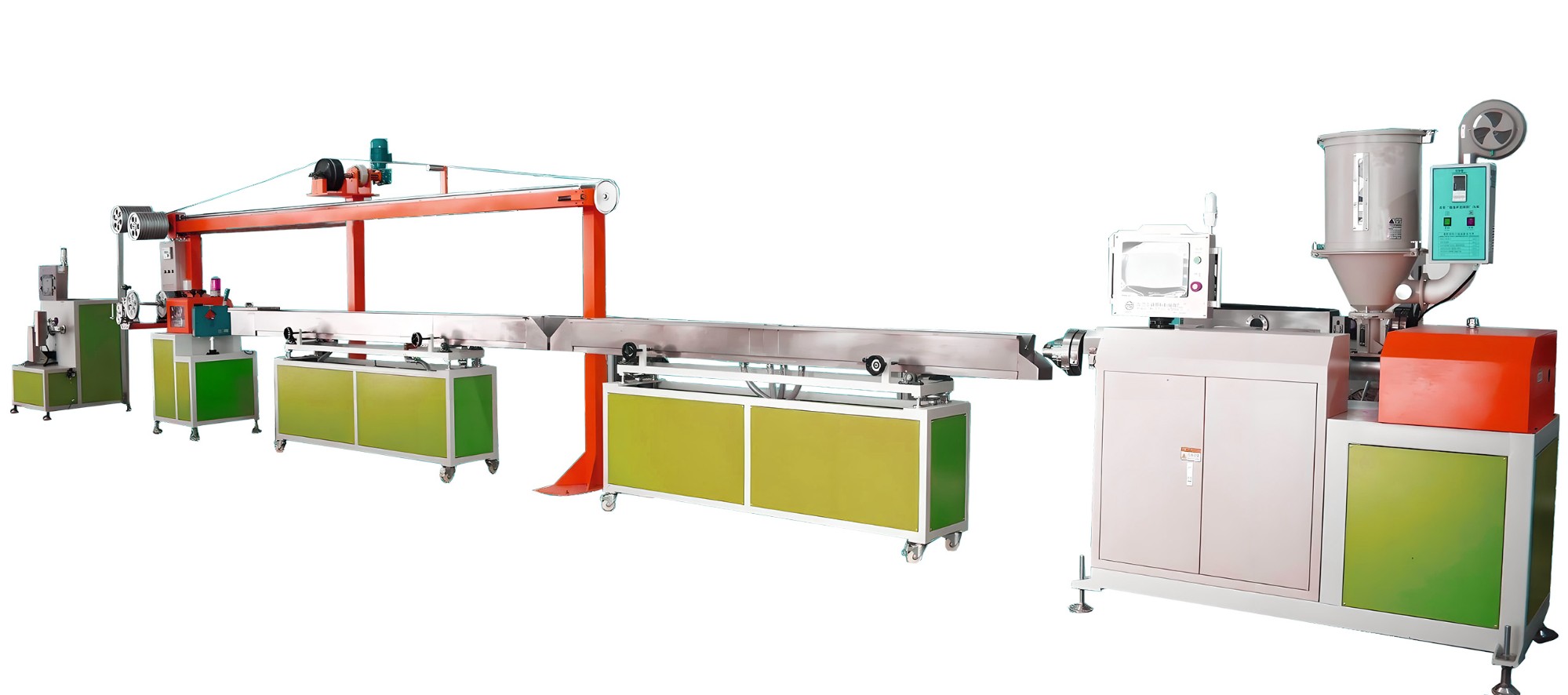

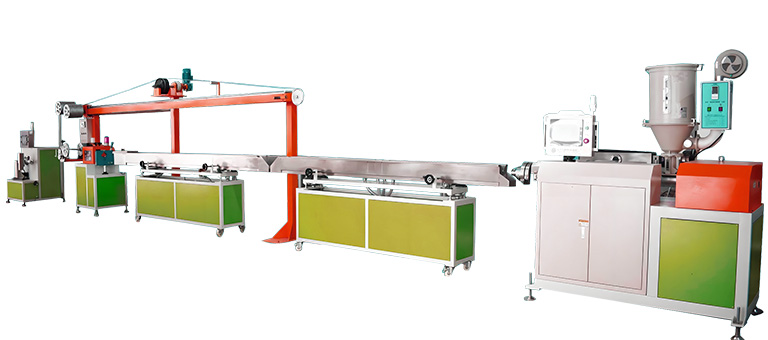

ABS/PLA 3D printing consumables production line

- Product Item : JSD-J035A-1

- Category: Extruder

- PE film blowing machine

- PLA film blowing machine

- PBAT film blowing machine

- ABS/PLA 3D printing consumables production line

By combining the advanced thermoplastic properties and precision extrusion technology of ABS/PLA materials, Zhitong successfully developed an ABS/PLA 3D printer consumables production line at the end of 2012, which is suitable for the production of 1.75mm and 3mm 3D printer consumables. Based on the production processes of different materials, Zhitong has focused on solving the following issues:

How to ensure the accuracy and stability of ABS/PLA consumables: Our factory can achieve a roundness of 0.02mm.

How to improve the production capacity of ABS/PLA consumables production lines: Some materials can reach speeds of over 100m/min

How to solve the problem of mixing uniformity when producing different colors: it has been solved through screw design.

How to ensure online moisture removal during high-speed production: Through graded processing, the direct packaging effect has been achieved.

How to solve the bubble problem in consumables: By adjusting the raw materials and extrusion process, it has been solved.

How to produce 3D printing production lines for other materials: Our company is also continuously developing printing consumables such as PC, heat dissipation PA, water-soluble material PVA, carbon fiber, graphene, and high-temperature resistant material PEEK, in addition to ABS/PLA.

High production capacity: line speed can reach 30-100m/min

High precision: controllable roundness of 0.05mm, with a measurement accuracy of 0.02mm

Stable quality: There will be no large color difference, hollow materials or other defective products, and precise equipment and technology guarantee that users can rest assured.

Low energy consumption: The entire production line is energy-saving with variable frequency control, and the energy consumption of the production line is only 10 degrees per hour.

Easy to operate and learn: Even if you have no knowledge of the equipment, Songhu Plastic Machine allows you to independently produce in 2 days.

Small footprint: 30 square meters can accommodate the entire production line

The equipment is used to produce 3D printing silk for various materials,

and different production lines can be customized according to customer requirements for special materials and configurations.

Applicable materials: PLA/ABS/PETG/WPC/TPU

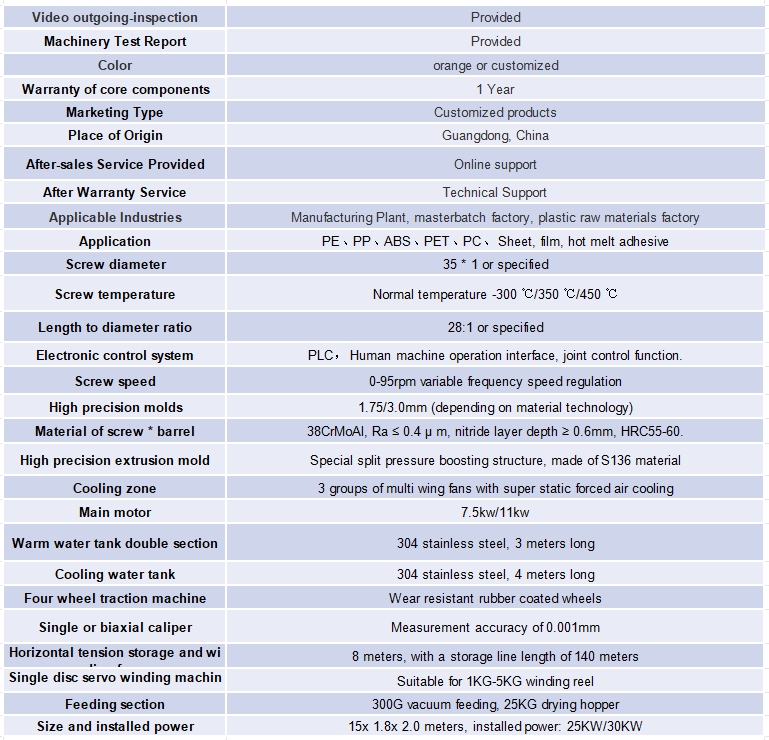

Key attributes

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Color | orange or customized |

| Warranty of core components | 1 Year |

| Marketing Type | Customized products |

| Place of Origin | Guangdong, China |

| After-sales Service Provided | Online support |

| After Warranty Service | Technical Support |

| Applicable Industries | Manufacturing Plant, masterbatch factory, plastic raw materials factory |

| Application | PE、PP、ABS、PET、PC、 Sheet, film, hot melt adhesive |

| Screw diameter | 35 * 1 or specified |

| Screw temperature | Normal temperature -300 ℃/350 ℃/450 ℃ |

| Length to diameter ratio | 28:1 or specified |

| Electronic control system | PLC, Human machine operation interface, joint control function. |

| Screw speed | 0-95rpm variable frequency speed regulation |

| High precision molds | 1.75/3.0mm (depending on material technology) |

| Material of screw * barrel | 38CrMoAl, Ra ≤ 0.4 μ m, nitride layer depth ≥ 0.6mm, HRC55-60. |

| High precision extrusion mold | Special split pressure boosting structure, made of S136 material |

| Cooling zone | 3 groups of multi wing fans with super static forced air cooling |

| Main motor | 7.5kw/11kw |

| Warm water tank double section | 304 stainless steel, 3 meters long |

| Cooling water tank | 304 stainless steel, 4 meters long |

| Four wheel traction machine | Wear resistant rubber coated wheels |

| Single or biaxial caliper | Measurement accuracy of 0.001mm |

| Horizontal tension storage and winding frame | 8 meters, with a storage line length of 140 meters |

| Single disc servo winding machine | Suitable for 1KG-5KG winding reel |

| Feeding section | 300G vacuum feeding, 25KG drying hopper |

| Size and installed power | 15x 1.8x 2.0 meters, installed power: 25KW/30KW |

Packaging and delivery

Supply Ability

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China