Flat vulcanization machine

- Product Item : JSD-P310A-1

- Category: Flat vulcanization machine

- Small open mill

- 9-inch open mill

- PVC open mill

- Silicone open mill

The cold and hot double-layer tablet press (flat vulcanization machine) is powered by an oil cylinder and is suitable for rubber and plastic raw materials, pigments, lubricants, chemical raw materials, etc. Put each raw material into a mold, clamp it between the electric heating plates of the machine, apply appropriate pressure, temperature, and time to dissolve and discharge the raw material, then apply maximum pressure to shape the material into thin sheets for testing and inspection. Promote product development and sampling. It is the foundation of large-scale production and can greatly help reduce transaction time and costs with customers

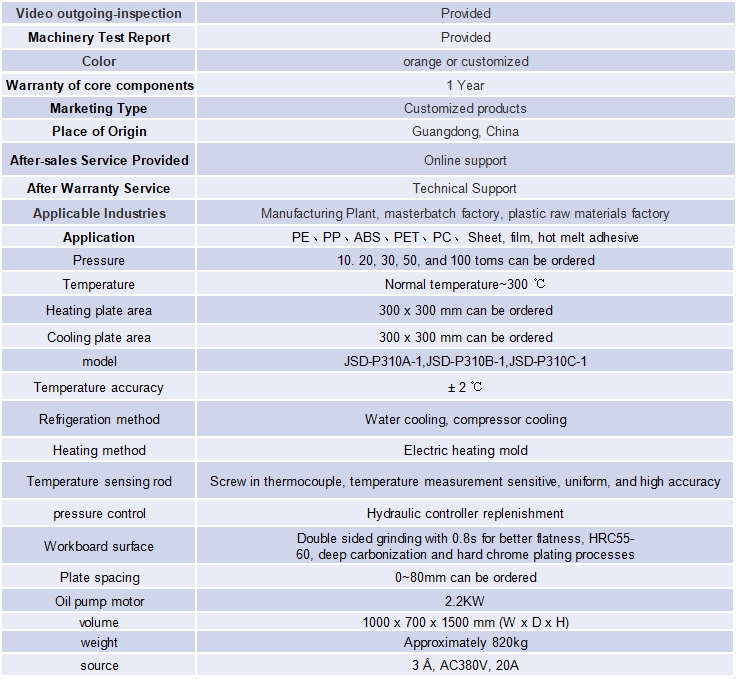

Key attributes

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Color | orange or customized |

| Warranty of core components | 1 Year |

| Marketing Type | Customized products |

| Place of Origin | Guangdong, China |

| After-sales Service Provided | Online support |

| After Warranty Service | Technical Support |

| Applicable Industries | Manufacturing Plant, masterbatch factory, plastic raw materials factory |

| Application | PE、PP、ABS、PET、PC、 Sheet, film, hot melt adhesive |

| Pressure | 10. 20, 30, 50, and 100 toms can be ordered |

| Temperature | Normal temperature~300 ℃ |

| Heating plate area | 300 x 300 mm can be ordered |

| Cooling plate area | 300 x 300 mm can be ordered |

| model | JSD-P310A-1,JSD-P310B-1,JSD-P310C-1 |

| Temperature accuracy | ± 2 ℃ |

| Refrigeration method | Water cooling, compressor cooling |

| Heating method | Electric heating mold |

| Temperature sensing rod | Screw in thermocouple, temperature measurement sensitive, uniform, and high accuracy |

| pressure control | Hydraulic controller replenishment |

| Workboard surface | Double sided grinding with 0.8s for better flatness, HRC55-60, deep carbonization and hard chrome plating processes |

| Plate spacing | 0~80mm can be ordered |

| Oil pump motor | 2.2KW |

| volume | 1000 x 700 x 1500 mm (W x D x H) |

| weight | Approximately 820kg |

| source | 3 Å, AC380V, 20A |

Packaging and delivery

Supply Ability

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China