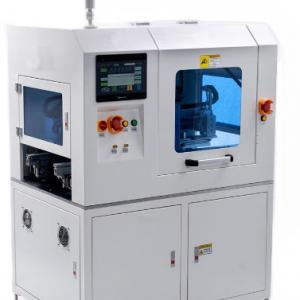

Rotary V-slot divider

- Product Item : JS D-B010A-1

- Category: PCB slitting machine

- Multifunctional slitting machine

- PCB Splitting and Swinging Integrated Machine

- Saw blade slitting machine

- Non metallurgical tool splitting machine

It can achieve automatic slitting in both V slot X and Y directions, and clean and burr free slitting of aluminum substrate, copper substrate, FR4, and fiberglass board. The slitting machine can connect to the assembly line to achieve fully automatic slitting without the need for manual placement; The cut boards are transported by the assembly line, which greatly saves manpower and fully realizes unmanned board splitting operations. When changing products, you can directly exchange the blade mold and suction cup parts without the need for manual adjustment, which greatly saves time.

Features of the online rotary V-slot divider:

1. A machine is equipped with a lower cutting die module on the machine, and the PCB board is sent out to the predetermined track through the upper board mechanism; Move the robotic arm over and use a vacuum nozzle to transport the PCB board onto the cutting die of the slitting machine.

2. After placing the PCB on the lower knife mold module; Move to the slitting position, move the circular knife on the machine to slitting the PCB board. After completing the translation slitting, move the lower knife mold module to the slitting position again; Until the horizontal plate is precisely rotated, the hollow platform automatically rotates 90 degrees to cut the vertical plate.

3. After the machine finishes cutting the PCB, the knife mold and knife group exit; The board picking robot moves over and sucks up the cut PCB board and the waste edge at the same time. It then moves to the waste frame to put down the waste, and then moves to the material tray on the receiving mechanism to arrange the product and send it away by the transportation line.

4. There is an industrial vacuum cleaner under the machine cutting blade mold to remove PCB dust.

Note: The cut small PCB boards can be automatically placed in the material box (tray, or directly placed on the assembly line) according to customer requirements and transported by the assembly line.

5. This device is suitable for the PCB board splitting work after the plugin.

6. Equipped with functions such as automatic feeding, automatic cutting, and automatic plate collection, the machine operation is simple and fast.

7. The setting of various parameters fully ensures the continuity of board feeding and splitting.

8. The main transmission components use precision stepper motors and SMC pneumatic components, with high precision in repeated positioning.

9. The whole machine adopts PLC+touch screen control, with a simple and convenient operating interface.

10. The work area is protected by safety gratings

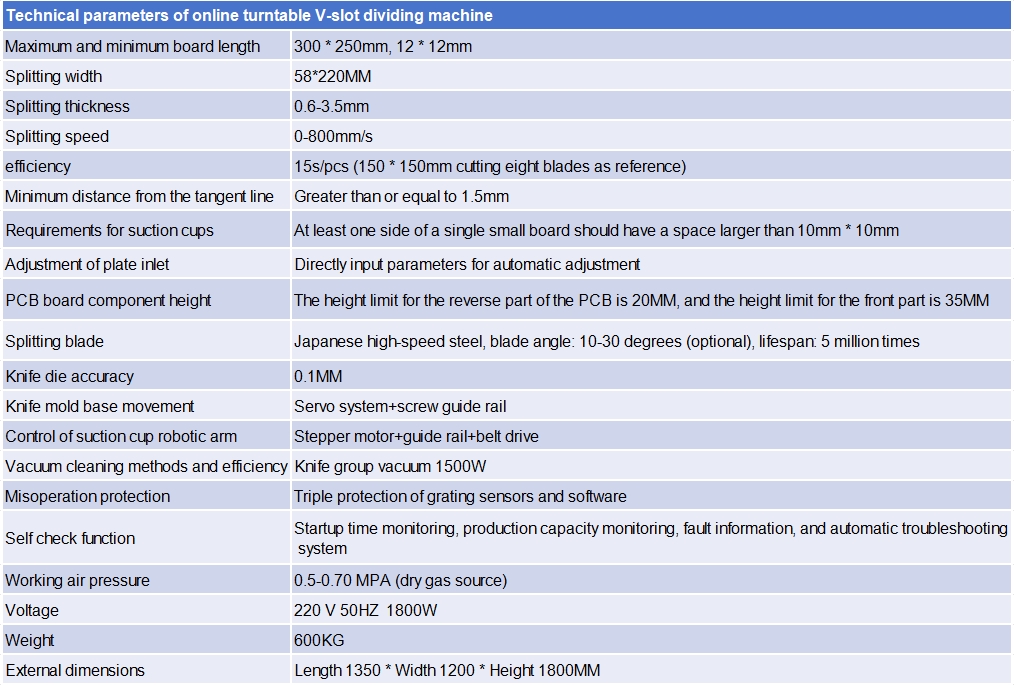

| Technical parameters of online turntable V-slot dividing machine | |

| Maximum and minimum board length | 300 * 250mm, 12 * 12mm |

| Splitting width | 58*220MM |

| Splitting thickness | 0.6-3.5mm |

| Splitting speed | 0-800mm/s |

| efficiency | 15s/pcs (150 * 150mm cutting eight blades as reference) |

| Minimum distance from the tangent line | Greater than or equal to 1.5mm |

| Requirements for suction cups | At least one side of a single small board should have a space larger than 10mm * 10mm |

| Adjustment of plate inlet | Directly input parameters for automatic adjustment |

| PCB board component height | The height limit for the reverse part of the PCB is 20MM, and the height limit for the front part is 35MM |

| Splitting blade | Japanese high-speed steel, blade angle: 10-30 degrees (optional), lifespan: 5 million times |

| Knife die accuracy | 0.1MM |

| Knife mold base movement | Servo system+screw guide rail |

| Control of suction cup robotic arm | Stepper motor+guide rail+belt drive |

| Vacuum cleaning methods and efficiency | Knife group vacuum 1500W |

| Misoperation protection | Triple protection of grating sensors and software |

| Self check function | Startup time monitoring, production capacity monitoring, fault information, and automatic troubleshooting system |

| Working air pressure | 0.5-0.70 MPA (dry gas source) |

| Voltage | 220 V 50HZ 1800W |

| Weight | 600KG |

| External dimensions | Length 1350 * Width 1200 * Height 1800MM |

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Jason Long

Mobile:+86 13686167553

Tel:+86 19118702155

Whatsapp:8619118702155

Email:longjason688@gmail.com

Add:Dongguan,Guangdong, China